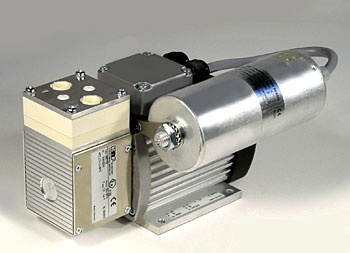

Diaphragm Pumps with Explosion Protection to ATEX Directives

The safety requirements which apply to equipment used in rooms in which there is an explosion hazard have been standardised throughout Europe in Directive 94/9/EU (often referred to as ATEX). An important new aspect is that whereas the old regulations covered only electrical equipment, the new ones include mechanical equipment as well. The result is that, from the point of view of explosion protection, a pump must be viewed as consisting of two units: the drive section (drive motor, an electrical device) and the working section (the pump part, a non-electrical device).

As a well-established manufacturer of diaphragm pumps for conveying, evacuating and compressing neutral and aggressive gases, KNF Neuberger has analysed and put into practice the measures necessary for explosion protection. Both external (environmental) explosion protection and internal (within the pump head) are taken into account. Numerous design details and the careful selection of materials have lead to pump designs that fulfil the ATEX requirements.

At KNF, pumps for use in rooms in which there is an explosion hazard are built up specifically for each Customer from a modular system, so that the precise requirements of each application can be taken into account. Given the knowledge of the conditions under which the pump is used, KNF engineers carry out calculations for every pump supplied to ensure that the temperature of the medium handled will remain below the ignition temperature, even when the pump is operating at its maximum permissible pressure.

The production program of explosion-protected pumps to ATEX directives covers the following performance spectrum:

- flow rate at atmospheric pressure up to 220 l/min,

- ultimate vacuum down to 53 mbar abs,

- pressures up to 4 bar gauge.