Active Fire Protection in Hazardous Materials Warehouses

Stored goods are combustible, moderately or highly inflammable, or perhaps even capable of spontaneous ignition. They often have fire or explosion-conducive characteristics as well...

Stored goods are combustible, moderately or highly inflammable, or perhaps even capable of spontaneous ignition. They often have fire or explosion-conducive characteristics as well. And materials may react strongly to their own combustion residues, resulting in poisonous by-products or gases. Fire prevention concepts based on reducing hazard potential from the beginning have proven effective at keeping these dangers at bay.

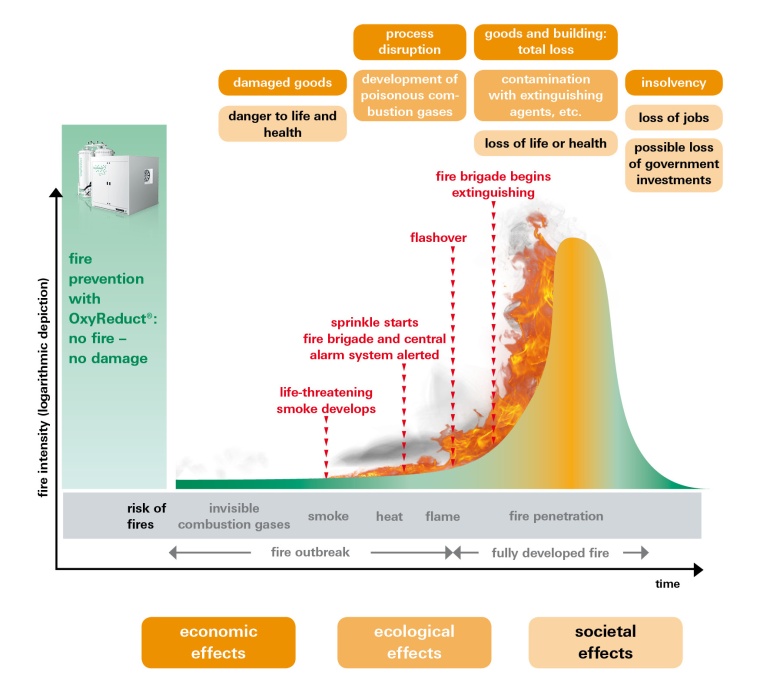

When it comes to systematic fire prevention, the goals are clear: protecting humans, animals, health and the environment. Business-related concerns are important as well, such as protecting the stored goods against loss, preventing damage to the warehouse itself (including its investment-intensive automation systems) and, above all, maintaining normal business operations and thus ensuring the company’s continued delivery capabilities. Disruptions to operating processes should occur neither due to false alarms nor as a result of fire suppression scenarios involving time-consuming, expensive cleaning and disposal work.

No Conventional Approach

BASF Coatings AG had to keep all of these factors in mind when comparing different fire prevention systems for the new distribution centers at their Münster-Hiltrup location. The global chemicals corporation‘s high rack storage facilities were to house innovative, high-value lacquers for industrial and automotive applications, so water and foam-based extinguishing systems were out of the question: even if the fires were successfully suppressed, the lacquers would be rendered unfit for sale. Another potential drawback would have been the need to install retaining structures to collect the contaminated extinguishing water, which would then need to be handled as toxic waste for disposal purposes. An automatic CO2 extinguishing system would have required them to keep an enormous amount of carbon dioxide on hand, enough to flood the warehouse’s 165,000 m³ of storage volume with CO2 in fire-suppressive concentrations. And, ultimately, they considered the inert gas’ harmful effects on human health that was incompatible with company policy.

Redundant Fire Suppression

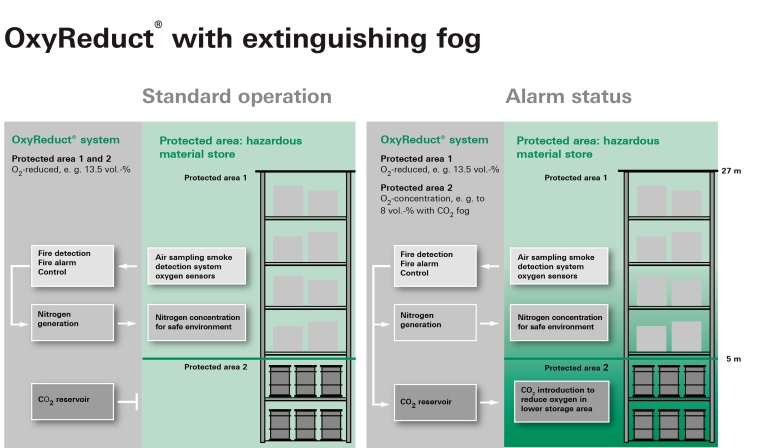

One central aspect of BASF’s security concept is to ensure that the lacquers – which are classified as hazardous materials – do not represent a fire danger, which meant they had to ensure there was no way a fire could break out. This is why, based on their goals of preventing explosions, maintaining business operations, preserving human health, and protecting the environment, BASF decided to employ active fire prevention by means of oxygen reduction.

“We were faced with a difficult task that we could not accomplish using conventional safety and security technology,“ said Dr. Peter Bachhausen, Head of Safety and Environmental Protection at BASF Coatings AG. “We needed a different trick: oxygen levels in the new warehouse will be permanently lowered to 13% volume, because fires cannot develop in places where there is not enough oxygen. Our plant fire department conducted an extensive series of tests, trying to set fire to a test warehouse – all in vain.“ As an additional security measure, BASF also decided to stop using methanol, methyl acetate and methylal in their lacquers as they would have remained flammable even at oxygen concentrates below 13% volume.

Active Fire Prevention

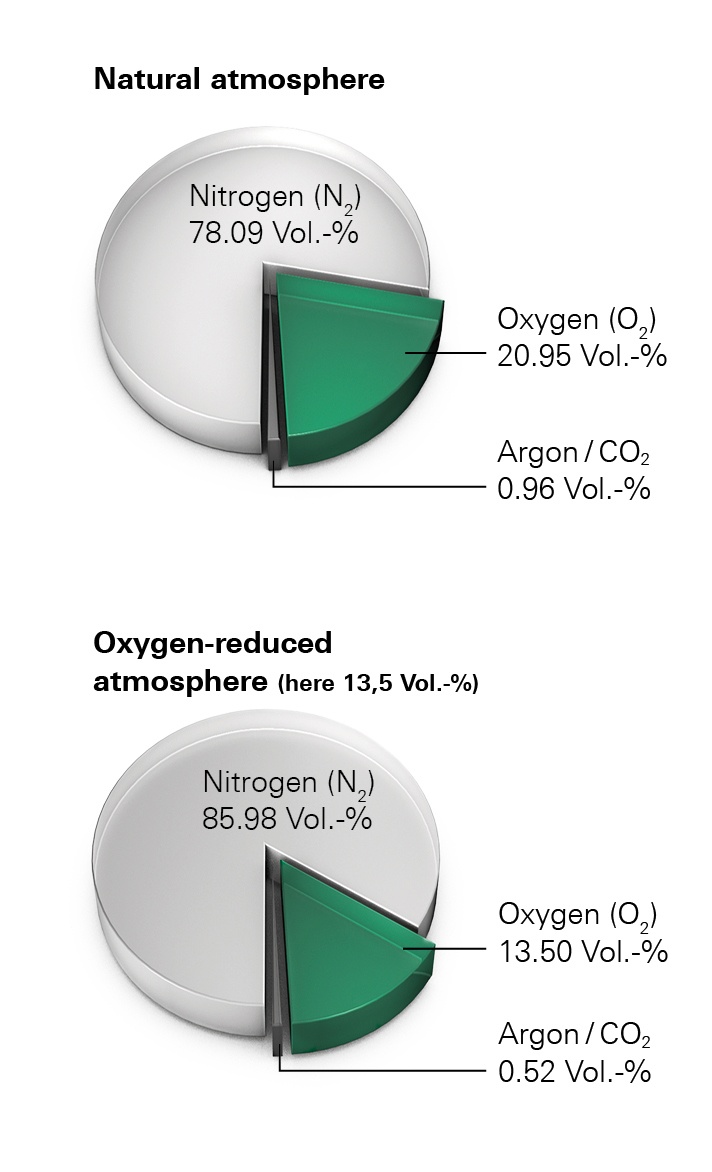

In 1994, the fire prevention specialists and system manufacturers at Wagner became the first in Germany to employ nitrogen as an extinguishing agent. When used in gas extinguishing systems, nitrogen displaces the oxygen in the protected area when a fire breaks out so as to deprive the fire of the air it needs to ‚breathe‘. Wagner drew upon its extensive knowledge of fire formation and suppression when developing the OxyReduct fire prevention system, a system that generates nitrogen and continually feeds it into the protected area, thus minimizing the risk of a fire breaking out in the first place. The nitrogen is introduced in a controlled manner in order to keep the oxygen level below the ignition threshold at all times, meaning that it is not physically possible for a fire to break out.

most read

GIT SECURITY AWARD 2026 - The winners have been announced!

GIT SECURITY AWARD 2026: The best safety and security solutions of the year - now an overview of all winners

Is Your Venue Ready for Martyn’s Law?

Martyn’s Law demands stronger security by 2027. Is your venue prepared to protect and respond?

Integrated and Futureproof: Traka’s Next Chapter

Interview with Stefni Oliver on Traka’s Vision for the Future

Between War and Peace: Hybrid Attacks and Their Impact on Critical Infrastructure

FOCUS TOPIC GERMANY - Hybrid attacks and drones: Security risks for Germany, its companies and critical infrastructure.

Airbus Defence and Space: Security as a strategic pillar of Europe's defense capability

Airbus Defence and Space protects sites, technologies and employees with modern security and cyber solutions - strengthening Europe's resilience in uncertain times