Charging and Storing Lithium-Ion Batteries Correctly

Lithium-ion batteries offer many advantages. They are long lasting, have a high energy density and are only slightly self-discharging. The batteries are therefore particularly practical for many devices in the industrial sector as well as in security technology. However, one thing should always be borne in mind: Lithium and many of its compounds are highly flammable and highly reactive. Certified and GS-tested type 90 safety cabinet models enable the highest safety requirements to be met when storing and charging lithium-ion batteries.

Lithium-ion batteries are indispensable today and enable a wide variety of applications. When handled properly, they are also safe to use. However, technical defects or improper handling of the battery types harbour an increased risk of fire due to their high energy density. The risk increases as soon as the batteries are charged unsupervised, for example outside working hours. The VdS 3103 leaflet from the German insurers (GDV e. V.) on loss prevention provides information on the safe storage of lithium-ion batteries. It becomes clear: Batteries should always be treated as hazardous substances. It is therefore important to know and comply with the safety rules for the batteries used and to charge and store them in a safety cabinet. The GS test standard EK5/AK4 22-01 was developed to take account of the potential hazards. This clearly and independently defines a test standard for safety storage cabinets for the active and passive storage of lithium-ion batteries.

What Does GS mean?

The GS certification stands for "Geprüfte Sicherheit“ (tested safety) and is a German seal of approval for the safety and quality of a product. The GS certification for lithium cabinets defines the current state of the art by prescribing specialised tests for lithium cabinets in addition to the German Product Safety Act (ProdSG). The German Product Safety Act, in turn, is the implementation of the European Regulation on General Product Safety (EU 2023/988). The EU regulation contains clear and detailed requirements that must be implemented by all EU member states. Safety storage cabinets that have undergone a complete test and subsequent certification in accordance with this test principle are suitable for the storage and unattended charging of new and used batteries and are labelled with the GS seal. Just like the new Ion-Line Ultra safety cabinet from Asecos.

Maximum Fire Protection

The Ion-Line Ultra guarantees double protection in the event of fire, as the GS test requires: 90 minutes of fire resistance from the outside in and from the inside out. While the 90-minute fire protection for the storage of hazardous substances (such as flammable liquids or pressurised gas cylinders) has long been a matter of course, the high level of protection has now also become established for lithium-ion batteries. In order to determine the fire resistance of the Ion-Line Ultra cabinet, a fire test was carried out from the outside to the inside in accordance with DIN EN 14470-1:2004-07, albeit under significantly more stringent conditions.

The temperature increase inside the cabinet must not exceed 100 Kelvin after 90 minutes – in comparison: 180 Kelvin when testing safety storage cabinets for the storage of flammable liquids. This stricter test value takes into account both the possible ignition of plastic housings and the melting temperature of separators in the cell. If the heat reaches the inside of the cell, this can immediately trigger a thermal runaway.

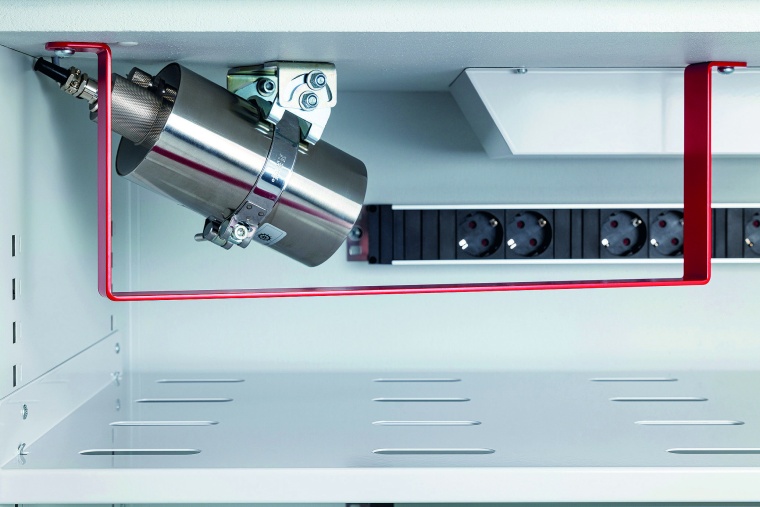

Another new feature of the GS-certified cabinet is its smoke-tightness. The entire cabinet design has been realised in such a way that, in the event of a battery fire, the resulting flue gas can be specifically discharged from the cabinet. Even if the supply or exhaust air openings are automatically closed in the event of a fire, the enclosure enables a defined pressure reduction and safe smoke extraction via a pressure relief flap in the head section. The design of the Ion-Line Ultra cabinet has been optimised for maximum safety and ergonomics. Batteries are easy to store and retrieve thanks to a 10-second door open hold and automatic door closure. Both cabinet doors can be opened simultaneously with a single door handle, and the permanent two-point locking system fulfils GS test requirements.

The Ion-Line Safety Concept

Charging lithium-ion batteries generates heat, which increases the hazard potential of the batteries. For this reason, the GS test for lithium cabinets requires proof of heating. The proof of heating is an essential part of the GS test of the Ultra cabinet. The verification proves that the temperature inside the cabinet does not rise above 60 °C even during the charging process. For this purpose, heat sources are distributed in the cabinet that simulate the heating of chargers and batteries during the charging process and the interior temperature curve is measured over 12 hours. The maximum permissible interior temperature of 60 °C was not exceeded at any time during the test. Sensors continuously monitor the temperature of the exhaust air flow and the fan speed is adjusted as the temperature rises.

In addition to heat, the new Ion-Ultra cabinets also detect smoke and immediately signal the alarm required by GS test principles on the cabinet housing by means of an LED light with a flashing function and colour change. This allows the user to recognise the type of danger at an early stage without having to open the cabinet. Every Ion-Line Ultra is factory-fitted with a potential-free switching contact that sends warning messages to a control centre in the event of damage. The cabinet can be evacuated to the outside thanks to the accessible base. This minimises damage to property and personal injury.

most read

Safety and Security in an Emergency: How companies take responsibility with strategic personal protection and amok prevention

Personal protection & amok prevention: strategic concepts, training & responsibility for corporate safety and security

When the Internet stumbles: Why DNS is important

When DNS fails, the internet stumbles-AWS outage proves resilience and redundancy are vital for digital trust

Integrated and Futureproof: Traka’s Next Chapter

Interview with Stefni Oliver on Traka’s Vision for the Future

Is Your Venue Ready for Martyn’s Law?

Martyn’s Law demands stronger security by 2027. Is your venue prepared to protect and respond?