Fire Testing: IR Cameras – Promising Tools in Fire Research

Infrared cameras detect energy in the form of infrared radiation from hot bodies and create a thermal image of the temperature differences. The technology is currently used for man...

Infrared cameras detect energy in the form of infrared radiation from hot bodies and create a thermal image of the temperature differences. The technology is currently used for many different applications and has in recent years increasingly been used in fire prevention measures. Among other things, infrared cameras contribute to improving fire safety in tunnels, including the Mont Blanc tunnel and the Bjørvika tunnel in Oslo, in that they can detect a fire much earlier than ordinary surveillance cameras.

SP Fire Research AS (SPFR) has an infrared camera of type FLIR GF-309. The camera measures temperatures from -40 °C til 1500 °C, it „sees" through smoke and flames and provides useful supplemental information in fire tests and to fire research. The infrared camera provides visualization of temperature distribution on the surface of a specimen, and thermal video sequences show the temperature distribution changes with time. The sensitive optics of FLIR GF-309 can detect temperature differences of less than 25mK.

Finding the „Hot spots"

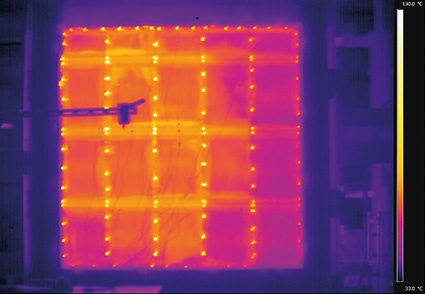

Our infrared camera can be used to visualize and detect so called „hot spots", i.e. areas of a specimen that reaches substantially higher temperatures than the rest of the specimen, during exposure to a fire. Figure 1 is a good illustration of this. Here, the fire resistance of a non load-bearing wall with steel beams and two layers of ordinary plaster on each side is tested in a vertical furnace. The infrared image clearly shows areas where the surface of the wall has elevated temperatures.

The temperature of the „hot spots" can be extracted by analysing the infrared pictures, either directly during the test or afterwards. This way it is possible to ensure that the hottest areas actually are the ones that are analysed, as opposed to using thermocouples, where the measuring points are predefined before the test.

Detecting the local temperature growth is useful for anyone who develops products and structures that are meant to resist fire. Areas that are particularly exposed to heat can be detected and thus improved in further product development. This is useful information for most product types, for example for passive fire protection, pipes, panels, fire doors, walls, windows, and especially for products with potential weaknesses such as joints and connections.

Advanced Analysis

Another advantage of the infrared camera compared to conventional thermocouples is the large amount of measurements possible. The number of measurement points is limited when using thermocouples due to time and cost aspects. In addition, the thermocouples are, as previously mentioned, placed in assumed strategic positions. However there is no guarantee that it is exactly at these positions that the most interesting and critical temperatures will appear.

There are no limits (The measuring points are limited by the number of pixels in the resolution of the camera.) to the number of measurement points when using the infrared camera and its software. In addition, it is possible to measure maximum, minimum and average temperatures of specific lines or areas, and also see how these change over time. Furthermore, a set-up can be applied where all points above or below a certain temperature is marked with a specified colour. To date, the use of infrared cameras is not meant to replace thermocouples but rather to be used as a supplement.

Heat Dissipation in Steel Structures

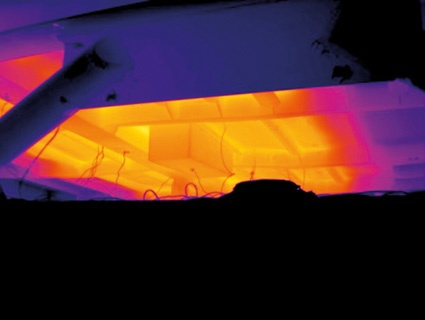

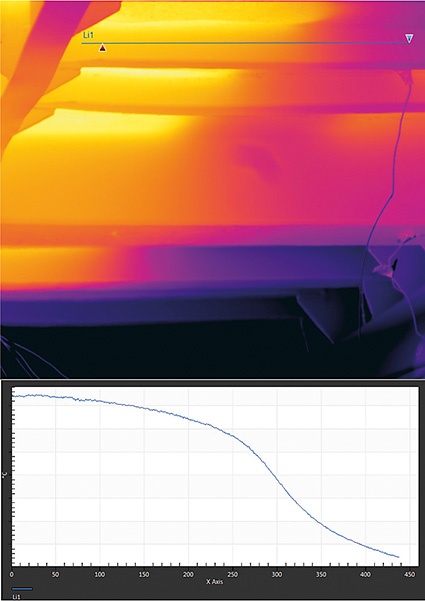

In a previous project conducted at SPFR, the load carrying capacity of a fired exposed steel structure was tested in a furnace for downwards heat transfer, built by SINTEF NBL (ref. Brandposten no. 48, 2013). The test simulated a fire on the deck of an oil platform, and the effect of the fire on the underlying steel structure was examined.

During the project the infrared camera was used to analyse and visualize how heat was dissipated within the steel. Figure 2 clearly illustrates how different areas in the structure differ in temperature. In Figure 3 the temperature profile of a steel beam is shown. The temperature changes considerably with the distance to the heat exposure. Such a test is suited for revealing how a structure is affected by a severe fire, and how quickly heat is dissipated to other parts of the structure that is not directly exposed to fire. This may, for example, indicate whether it is necessary to apply passive fire protection on all or part of the construction.

Tunnel fire

The use of infrared cameras can provide valuable information during tunnel fire tests. Experiments in tunnels often involve very heavy smoke production, and it is challenging to get good pictures and videos. The infrared camera can „see" through smoke, thus providing valuable information about the fire development and the changes in temperature in the tunnel over time.

Modelling

For those involved in mathematical modelling of fires, the infrared camera can be used to map surface temperatures over complete geometries, providing a basis for validation of calculations.

most read

When the Internet stumbles: Why DNS is important

When DNS fails, the internet stumbles-AWS outage proves resilience and redundancy are vital for digital trust

Assa Abloy's battery-powered Aperio KL100 secures lockers

Boost workplace security and operational flexibility by securing more than just doors.

Airbus Defence and Space: Security as a strategic pillar of Europe's defense capability

Airbus Defence and Space protects sites, technologies and employees with modern security and cyber solutions - strengthening Europe's resilience in uncertain times

Integrated and Futureproof: Traka’s Next Chapter

Interview with Stefni Oliver on Traka’s Vision for the Future