FLIR Systems: thermal imaging cameras for one of Europe‘s largest refineries

FLIR Systems: thermal imaging cameras for one of Europe‘s largest refineries. Polski Koncern Naftowy Orlen, better known as PKN Orlen, is one of the largest crude oil refineries in...

FLIR Systems: thermal imaging cameras for one of Europe‘s largest refineries. Polski Koncern Naftowy Orlen, better known as PKN Orlen, is one of the largest crude oil refineries in Europe. More than 20,000 employees run the company‘s seven refineries, of which three are in Poland at Plock, Trzebinia and Jedlicze. The company has further locations in the Czech Republic and a refinery in Lithuania. It has recently started to use SR-100 thermal imaging cameras from FLIR Systems.

The pipeline that delivers crude ‚Ural‘ oil to PKN Orlen is called “Friendship“, or “Druschba“ in Russian. The Polish company has specialized in the processing of this crude oil into unleaded petrol, diesel, heating oil and kerosene for aircraft – but plastics and other crude oil products are also part of the process. As well as this, the company runs a large sales network to sell to end-users.

Security for the Main Factory in Plock

The main petrochemical plant is the refinery complex in Plock, some two hours‘ drive from Warsaw. The plant stretches over more than 800 hectares and is one of the most modern and progressive factories of its type in the whole of Europe. Top priority is to prevent unauthorized access – not only at the main gate: the whole compound is highly secured. The reason for the extensive security measures lies, for example, not only in the fact that unauthorized persons might endanger the 24- hour production.

A facility where so many different chemical processes are taking place must also be secured for other reasons, one of which is protection against theft. It is easy to overlook the amount of valuable equipment and materials that are in use: copper and other metals are valuable raw materials that can inspire theft and the running of stolen goods. It is not easy to secure such a compound, as Jacek Kotulski, security expert and coordinator at PKN Orlen in Plock explains. “The factory consists of almost 70 individual production systems that are spread over an area of over 800 hectares. As in any other high security area, we have installed a palette of different security measures and equipment to be sure that no one enters the factory compound without us knowing about it. CCTV surveillance cameras, video analysis, fences – all these are installed at various places within the compound and work together to keep trespassers out.”

Thermal Images – when It‘s Dark, Foggy, Smoky or Steamy

It is a special challenge also to ensure the security of this large site when it‘s dark – the solution was found in thermal imaging technology. “I already knew about thermal imaging technology and therefore made contact with Mr. Swies of Agtes, a distributor of FLIR Systems in Poland, who showed me the systems in action“, explains Jacek Kotulski. “We decided almost immediately to purchase and install a number of thermal imaging cameras, in this case the SR-100 model. The reason why we chose this specific model was because of its excellent range. The SR-100 will already discover a target the size of a grown man at a distance of not less than 1.6 km. And that in total darkness under all conceivable weather conditions.“

The SR-100 thermal imaging cameras were installed along the entire perimeter and also in particularly sensitive high-security areas. The cameras are permanently mounted and constantly monitor the same area. There is always a video surveillance system in the direct vicinity with CCTV dome cameras. “If an alarm is raised and weather conditions permit, we can get a more accurate view of the specific situation from the surveillance cameras. Otherwise we will dispatch a patrol to get a report on the situation“, says the security coordinator.

The thermal imaging technology is also very helpful on the frequent foggy days in Plock. “Although the range of the thermal imaging cameras is also affected by fog, they allow us to see a lot more than is possible with a conventional CCTV surveillance camera“, says Jacek Kotulski. “There are of course a number of production processes in the refinery that create a lot of steam and smoke. The SR-100 thermal imaging cameras have also proven to be very useful here to see through the steam and smoke. That‘s just not possible with normal surveillance cameras.“

Thermal Imaging Technology and Video Evaluation

One reason for the choice of fixed thermal imaging cameras is their good compatibility with the video evaluation in the refinery. Jacek Kotulski: “By choosing fixed systems instead of the optional pan/tilt mechanism we have reduced the number of false alarms. The thermal imaging cameras from FLIR Systems work very well with our existing image analysis system. One of the advantages of thermal imaging cameras lies in the high-contrast image that they provide, not only at night but also under difficult light conditions where a conventional CCTV surveillance camera would not deliver a useable contrast level. That makes thermal imaging technology the best partner for our Object Video evaluation system“, adds Kotulski.

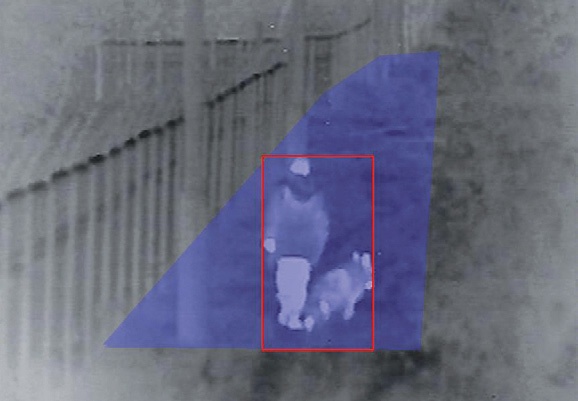

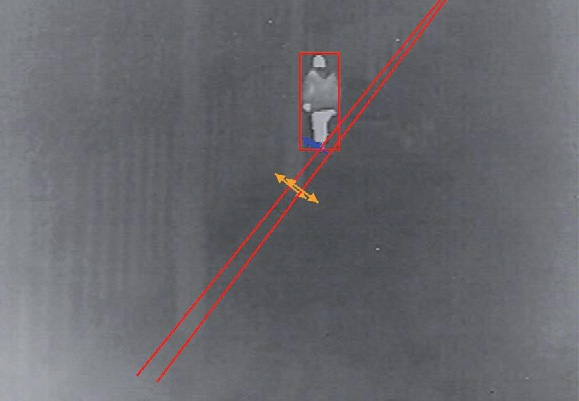

The images from the SR-100 cameras are transmitted via a BNC/fiber optic convertor over a fiber optic cable. At the end of this fiber optic cable another BNC/fiber optic convertor receives the signals and sends them to the Object Video processor. From there, the images are sent via Ethernet so that they can be seen anywhere. Jacek Kotulski: “But most of the time we are not looking at the thermal images ourselves because the computer does it for us. We run Object Video VEW 5.0 over the digital signal processing. Object Video Forensics is also installed as an additional add-on. Object Video uses algorithms to recognize objects and immediately generates meaningful messages such as real-time alarms or trigger signals for the automatic start of other applications“.

One of the algorithms, “trip wires“, sets off an alarm when someone or something crosses a specific line that can be defined in Object Video. Another algorithm is called “areas of special interest“ (AOI). AOI makes it possible to define an area to which no access is allowed. An alarm will also be automatically raised here if this area is entered or an imaginary border is crossed.

To limit the number of false alarms, the program has a number of filters. One of the automated actions that is controlled by Object Video is the immediate display of the thermal image on the monitor in the control room if an alarm is raised. As soon as that happens, the operator decides if it is necessary to implement further steps. Jacek Kotulskis‘ opinion is extremely positive: “The SR-100 cameras have proven to be a valuable tool for our security. They help us with perimeter protection, not only at night but also during the day – under all possible and impossible weather conditions.“

Bertrand Völckers

FLIR Systems

Contact:

FLIR Commercial Vision Systems

Tel.: +49 30 3730 3972

flir@flir.com

www.flir.com

most read

GIT SECURITY AWARD 2026 - The winners have been announced!

GIT SECURITY AWARD 2026: The best safety and security solutions of the year - now an overview of all winners

Integrated and Futureproof: Traka’s Next Chapter

Interview with Stefni Oliver on Traka’s Vision for the Future

Assa Abloy's battery-powered Aperio KL100 secures lockers

Boost workplace security and operational flexibility by securing more than just doors.

Training at Fraunhofer SIT: Strengthening resilience against cyber attacks

Knowledge in cyber security is evolving rapidly - continuous training is therefore important.