Jokab Safety: line and area gantry robots meet highest safety requirements

Jokab Safety: line and area gantry robots meet highest safety requirements. Bleichert Förderanlagen, a manufacturer of equipment for conveyors, factory automation, assembly and int...

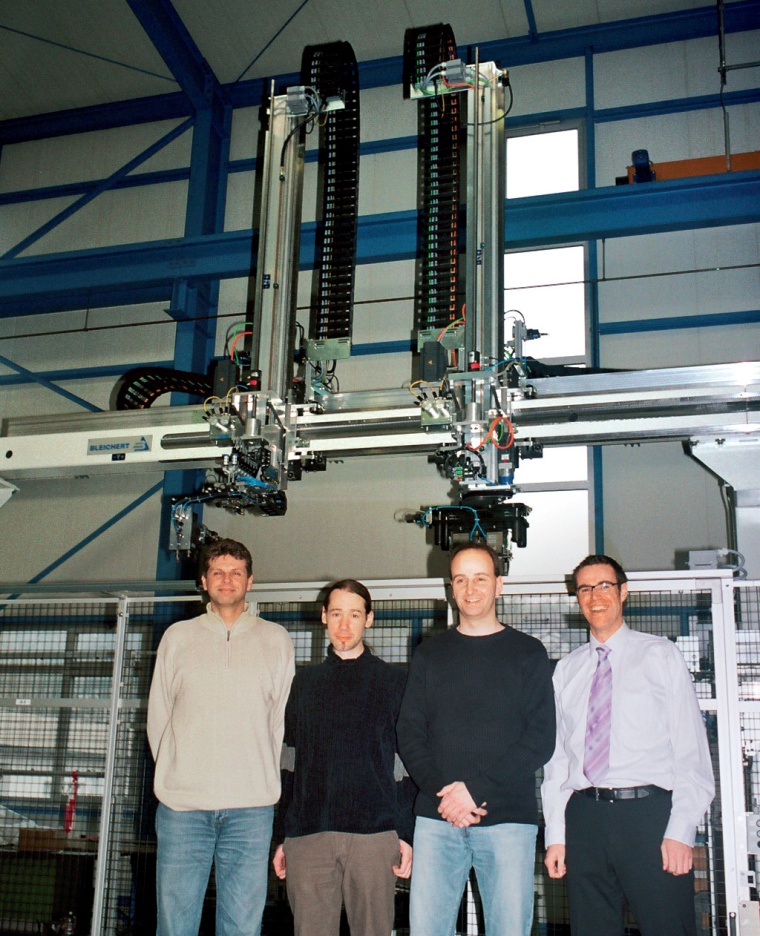

Jokab Safety: line and area gantry robots meet highest safety requirements. Bleichert Förderanlagen, a manufacturer of equipment for conveyors, factory automation, assembly and interlinking systems, has been using complete safety solutions from Jokab Safety for the protection of personnel and machinery for the past three years. These reach the highest safety category 4 according to EN 954-1.

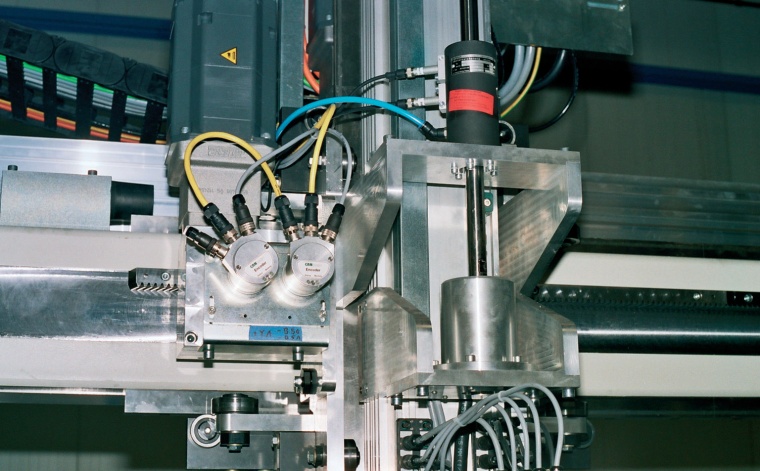

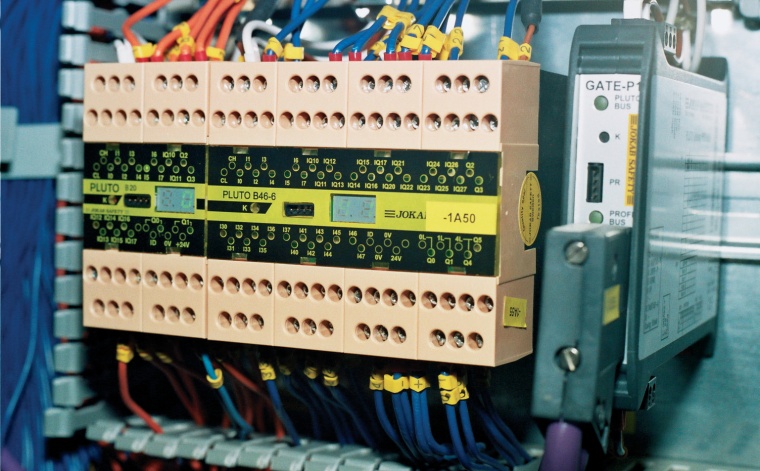

All safety functions on the new line and area gantry robots are managed and monitored by several Pluto B46, B16 and B20 safety PLC‘s (programmable logic controllers) in conjunction with JS-RSA 698 multiturn encoders and Focus safety barriers. This innovative solution greatly simplifies the design, provides a better overview as well as considerable cost savings on wiring, maintenance and stock-keeping. Quick Guard E fencing systems prevent unauthorised entry to the danger zone.

Highly Automated Production

The complete installation includes components from the company‘s automation, skid systems and montamatic/montarail systems (automated guided vehicles) product divisions. These enable the movement of workpieces weighing from as little as 1 kg up to 2 t kg within highly automated production facilities. They automatically feed, mount and stack, and thus smooth the entire production process.

A line gantry robot, for instance, can handle engine blocks by gripping, turning and laying them down on a precision roller conveyor. They are the heart of an interlinking system for engine manufacture, and are capable of moving heavy loads accurately in just a few seconds. Gantry robots are also used for shifting machine tools, for stacking, depalletising, and also as a storage system in conjunction with shelving and racking.

Demountable Aluminium Fencing

A new versatile aluminium fencing system called Quick-Guard E has been introduced that has a patented net-lock, a new mesh and new U-profiles. The net-lock makes it very easy to reconfigure and fasten the mesh against fence posts when production facilities are extended or moved. No horizontal extrusions between the posts are needed to keep the mesh in place, and centred mounting holes on the Smile E-stops make it easy to install them on the aluminium extrusions.

Jokab Safety employs an AutoCAD based program called SafeCAD to generate drawings in 3D, cutting lists, parts lists etc. and to make system designs in 3D in a short time. The drawings can also be used for installation purposes - special spreadsheet software makes it possible to quickly calculate the required components and to visualise a fencing system built from sections.

Position Control and Monitoring

The PR40 line gantry robot has two independent side shuttles and loads a friction welding machine with two different components to be assembled. The completed part is then heat-treated in a downstream machine and laid down on pallets in stacking cells. Full pallets are taken out manually and the corresponding stacking cells are loaded with empty pallets.

JS-RSA 698 multiturn absolute encoders monitor the horizontal position of the gantry trolleys, allowing the operator to change the pallets without any danger while the trolleys of the line gantry robot continue to load and unload the machines. The automatic and the manual parts of the process are thus decoupled, maximising line gantry robot output. The absolute encoders also avoid collisions between the independently driven gantry trolleys. They provide a resolution of 13 bits for the absolute position value and 12 bits (4096) for the number of revolutions.

To allow operators access to where a moving PR100 area gantry robot loads and unloads the different machine tools, coupled-motion horizontal Focus light curtains are used. These have a cross-section of only 35mm x 45mm, with a resolution of 14 mm for finger protection and 35 mm for hand protection. They are certified to category 4 of the EN/IEC 61496-1/2 safety standard and are very easy to install and configure. Inputs are provided for partial or complete muting of the beams.

Multitasking Safety PLC

Despite its width of only 90 mm, the new Pluto B46-6 master safety PLC is, up to now, the most powerful safety PLC on the market and meets the highest safety category 4 according to EN 954-1. With a total of 46 I/O‘s, six of which are individual safe outputs, it meets the growing need for a compact safety PLC module with more I/O‘s. Moreover, 16 I/O‘s can be used either as inputs or outputs and 24 inputs are provided for safety components and other sensors.

The system can be used both for safety monitoring and for controlling smaller machines by using the intuitive management software. A programming tool allows both TÜV-approved safety function blocks and free programming. An operator panel (Human- Machine-Interface HMI) can be connected directly to the serial interface or to the safety CAN-bus and, via a gateway, information from the Pluto safety bus can be transferred to other bus systems, such as Profibus, CANopen, Device- Net or Ethernet.

Single-source Benefit

Dieter Uhl (37), Export Manager at Bleichert, sees a specific advantage from the co-operation with Jokab Safety in that the Swedish manufacturer can deliver the complete safety solution from one source. If a device should fail, they only need to contact one single supplier with European, North American and Asian approvals. Formerly, the company used mechanical cam switches for position monitoring, and modifications of the equipment proved to be complicated and costly.

The new solution with absolute encoders now meets category 4 and is more precise and user-friendly.

Contact:

Jokab Safety AB,

Malmö, Sweden

Tel.: +46 300 359 00

Fax: +46 300 730 85

mats.linger@jokabsafety.se

www.jokabsafety.com

Bleichert Förderanlagen GmbH,

Osterburken, Germany

Tel.: +49 6291 93 304

Fax: +49 6291 93 399

duhl@bleichert.de

www.bleichert.de

most read

Is Your Venue Ready for Martyn’s Law?

Martyn’s Law demands stronger security by 2027. Is your venue prepared to protect and respond?

Safety and Security in an Emergency: How companies take responsibility with strategic personal protection and amok prevention

Personal protection & amok prevention: strategic concepts, training & responsibility for corporate safety and security

Integrated and Futureproof: Traka’s Next Chapter

Interview with Stefni Oliver on Traka’s Vision for the Future

Assa Abloy's battery-powered Aperio KL100 secures lockers

Boost workplace security and operational flexibility by securing more than just doors.