Master Of Observation: A conversation with Dieter Dallmeier

When you think about video technology from Dallmeier, you first of all think of the multifocal technology of the ‘Panomera’ cameras. Very large areas and views can be covered by this technology with comparatively few cameras – and it is a significant contributor to the success of Dallmeier. The cameras and recording systems as well as all the relevant software elements are manufactured in Regensburg, Germany. GIT SECURITY spoke with the company’s founder and its CEO, Dieter Dallmeier.

GIT SECURITY: Mr Dallmeier, you state very prominently on your company’s homepage that the value of a video security solution is never defined by its price...

Dieter Dallmeier: ... but solely by its quality and its economics. This has been shown to be true in practice time and time again from experience gained over more than 35 years of ‘video security technology made in Germany’, first as an installer, then a developer and finally as a manufacturer of end-to-end solutions. It may sound like a contradiction, but the products with the lowest overall operating costs can still be developed and manufactured even in high-wage Germany.

So, the most cost-effective solutions are produced in Germany, where wages are high. Could you explain that in a little more detail?

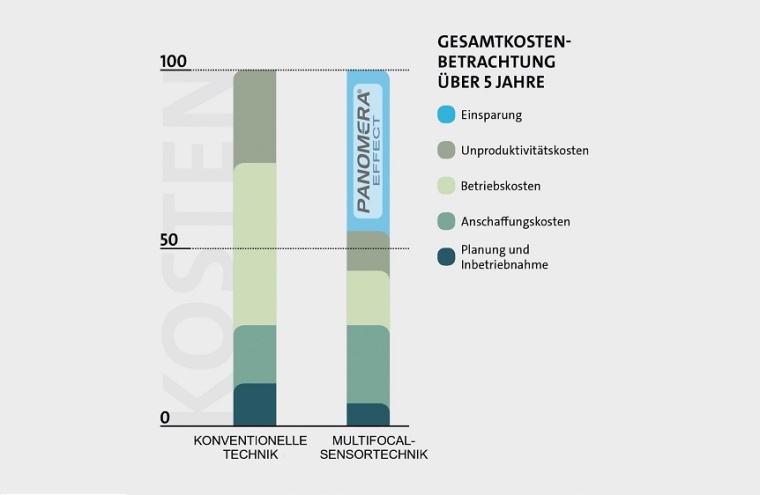

Dieter Dallmeier: In our industry, cost efficiency is not measured by the price of a camera, for example, but by the overall operating costs I have to spend in order to meet a certain security objective. These costs become smaller in direct proportion to how intelligently you can combine the factors of quality, durability, reliability and innovative, cost-saving technology. For example, if our customers can obtain a significantly better result than with comparable technologies by implementing a much smaller number of camera systems with our Panomera technology, then we have also delivered true added value, and specifically in a high-wage country.

What approach was responsible for Dallmeier’s continuous success over more than 35 years?

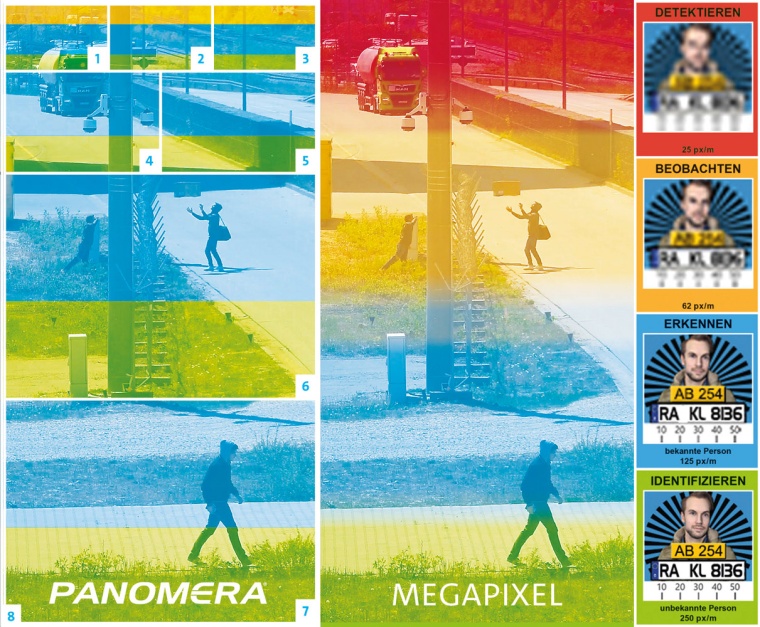

Dieter Dallmeier: Constantly rethinking how we can “make things easier”! A good example is the invention of the Panomera multifocal sensor technology itself. The classic approach of ‘more of the same’ – that is to say more and more megapixels together with more and more PTZ cameras – evidently did not solve the fundamental problem in video security technology: the objective of getting total coverage and recording of large areas and long distances with both an image resolution that is usable for the respective purpose and a manageable number of systems. It is no good to you if you capture the incident in a tiny corner of a public square in maximum resolution with a PTZ camera while things are happening in four other places that you can observe or record with megapixel or multisensor cameras, but you can’t make anything out in detail because of the insufficient resolution in precisely those background areas of the image. Or the operator has so many monitors in front of him that it is impossible to see any context.

So, we realized very quickly: a minimum resolution for the entire scene – that is to say a minimum resolution in as many regions as possible within an area to be captured that corresponds to the purpose of surveillance – is critically important. By using up to eight individual sensors with different focal lengths in one system – hence the term “multifocal sensor” – we precisely addressed these requirements from our customers in practically all relevant industries.

But you still need certain pixel values in order to be able to recognise and identify individuals?

Dieter Dallmeier: Exactly. The effective resolution with which a camera captures a given object in the scene is defined in DIN EN 62676-4 for video surveillance systems. The unit is “pixel density” which is expressed in pixels per metre (px/m). Accordingly, there are criteria for detecting events and processes (at least 62.5 px/m), recognizing known persons (at least 125 px/m) or identifying unknown individuals (at least 250 px/m). Of course, the resolution required is dependent upon the particular application. A World Cup football stadium like the Gazprom Arena in St. Petersburg must be captured in a different way than, say, a Safe City application for approximately 75,000 square meters in Cologne, which by the way only needs 60 Panomera systems to achieve total coverage at 250 px/m.

Of course, a guaranteed minimum resolution is only one of the most important performance indicators, not only for classic video surveillance and observation. It also ensures a guaranteed quality of data for analysis applications. After all – as with all data processing – a video analysis result can only ever be as good as its input data. This is a factor that many end users overlook all too often, and are then surprised by the poor quality of their analysis results.

To return to the economics. It would be a very rare customer who could completely ignore the costs...

Dieter Dallmeier: Costs are one part of the overall consideration. We are often asked “What does a camera like this cost?” But that is not a meaningful approach. One Panomera system replaces many traditional cameras. This has massive leverage effects on the overall operating costs: customers need fewer masts and mounting points, network components, cables, ditching, and also putting the systems into operation entails significantly less work. Then there are the savings realized during operation, because a lot less screens need to be monitored.

For installers, high quality and reduced complexity due to the smaller number of systems also translates to less maintenance and troubleshooting work. This is nothing less than an additional discount and is an outstanding instrument for strengthening customer loyalty. When paired with innovative technology this can potentially lead to substantial competitive advantages.

Would you be able to illustrate the calculation (a comparison of Panomera with other cameras) with an example?

Dieter Dallmeier: There are numerous examples of this type. In a recent Safe City project, the total of the procurement costs, that is to say for systems and infrastructure, and the cumulative operating and administration costs over five years came to a little over 1 million euros for the Dallmeier solution compared with 3.2 million euros for the alternative bid. We were recently visited at our headquarters by project managers from a US airline. They showed us figures according to which the costs of our solution came to almost exactly 50% of the competitor’s alternative solution – at the same time delivering a better resolution coverage and without taking into account the savings realized during operation, due to the smaller number of monitors and less operator time needed, for example.

It never ceases to amaze me how the picture changes when a genuine calculation of total costs is worked out instead of comparing the individual prices of cameras and recording systems. Incidentally, the consideration of the costs for ‘security per square meter of space’ is particularly illuminating. Using this calculation method, you get close to the price of a good carpet!

Let’s take another look at the Panomera cameras from a more technical point of view: The market doesn’t always make the clear distinction between a ‘multisensor system’ and a ‘multifocal sensor system’...

Dieter Dallmeier: A multisensor system claims only to accommodate multiple cameras with the same focal length in a single housing in order to obtain different viewing angles from one installation point. This undoubtedly reduces infrastructure costs, but it does not enable them to meet the requirement stated earlier – that of rendering the entire area in high resolution and thereby reducing the total number of systems.

Dallmeier systems are able to do this by combining lenses of different focal lengths in one system, depending on the intended application. This demands enormous technical effort and expertise and is at the core of our patented Panomera multifocal sensor technology. It is simply not possible to attain the advantages of such a solution using conventional cameras or a multisensor system, as also confirmed by the patent. And it should be noted, only the multifocal sensor system is patentable, the multisensor system is not.

The new Panomera W camera was launched in the autumn of 2019 – GIT SECURITY reported on this. Would you kindly give us a reminder of the improvements and innovations that came with it – particularly whencapturing large surveillance spaces?

Dieter Dallmeier: There are two versions of the Panomera system. The “S-Series” for areas and distances with coverage angles from 15 to 90 degrees. By the way, we launched the third generation of this version in October 2020. And now with the Panomera W-Series, users have a system that enables the advantages of multifocal sensor technology to be applied in 180 and 360-degree situations. Here too, operators can open an unlimited number of zoom windows and enlarge detail views, while maintaining exceptional control over large spatial relationships. With a minimum resolution of, for example, 125 px/m, they can cover an area of well over 1,000 square metres with just a single system.

Over the course of the various generations of the Panomera, about 200,000 hours of research and development have now been invested in the product – from which our new flagship Panomera W has benefited in particular. The most advanced chip and encoder technologies with an AI core make it possible to keep the camera series updated to the state of the art and therefore also able to meet future analysis requirements for a very long time to come.

You have already collected two prestigious design awards for it as well. How important is this aspect for your partners and customers?

Dieter Dallmeier: Very important. Our partners and customers have confirmed this in many conversations. For a long-lived product, it is all the more important that it appears timeless even after many years and, in particular, blends unobtrusively with architecturally delicate surroundings. For example, this also includes ensuring that all cables and the like are invisible but at the same time the systems appear as standalone, attractive objects. We engaged the services of industrial designers to achieve this, and can proudly claim that we have developed a truly extraordinary design language that embraces all the different Dallmeier cameras.

This is all about being economic during planning, installation and operation, and keeping demands on the on-site infrastructure low, isn’t it?

Dieter Dallmeier: Correct. Our “Mountera” mounting concept, which simplifies life for the installer with many innovations, was also born in design development. This way all our cameras can be easily installed by one-man with the ‘Quicklock’ system. A single-use handle for its part makes unpacking and handling easier at the construction site. The packaging material also serves as bubble-wrap protection while the devices are being carried around, and just one Allen key size is needed for all installation work. This reduces the installation time enormously, the ‘fun factor’ increases, and at the same time Mountera helps to drastically reduce costs.

Video analysis and AI are both becoming increasingly important. You were working with neural networks as early as 2001 – you develop these things yourselves in Regensburg. What are the new features that will have an impact in practice?

Dieter Dallmeier: Image quality is always synonymous with data quality for us. And this is an absolutely imperative prerequisite if we intend to be able to develop and pursue meaningful video analysis applications. Our customers reduce the number of false alarms at the perimeter these days by using AI-based object classification, they increase profitability in casinos with AI-based gaming table analysis, count people in stadiums or shorten the time needed to measure packaged goods in logistics, to name just a few examples. We are also be reorganizing and expanding our analysis portfolio in the near future. Our customers will then be able to compile the analysis functions that are relevant for them from a large number of analysis apps. And in larger installations it is important for us to consider each application case – depending on whether the analysis in the camera is sufficient or further processing should be carried out with prequalified data in separate server instances. Here too, the advantages of Panomera can again be exploited to the full, enabling users to analyze even very large spatial contexts.

At this point, we are no longer talking about just video surveillance and security, but also about the collection and use of data for process optimisation...

Dieter Dallmeier: Camera images serve as one of the simplest and smartest options to capture data from complex relationships. In this context, we often refer to them as ‘optical data sensors’. And of course, this also opens up entirely new functionality – from the automatic ‘on-the-fly’ measurement of packaged items in logistics through marketing optimization in shopping centers, stadiums or casinos, up to the direction of passenger flow in airports to reduce waiting times or to increase profitability in the shopping area. In the medium term, we expect the use of video analyses to become an indispensable component of data capture, either for process optimization or for business intelligence, in almost all industries.

Could you tell us about some customers or examples of use where this is already paying dividends?

Dieter Dallmeier: I think the most impressive examples come from our customers in logistics. Our system for video-based volume measurement enables automated measurement of parcels on pallets without the need to set the parcel down or stop the movement of the conveyor. As a result, general cargo logistics personnel save up to 95% of the time they normally need for measuring, and they can offer the measurement as an extra service.

Another example is package tracking in one of the largest package shipping enterprises in the world. Here, we reduce the search time spent tracking shipments that have been lost due to theft or other reasons by as much as 80%. The proportion of shipments our customer was able to find again with this system rose to almost 100%, because our system guarantees uninterrupted tracking of shipments. As a side effect, operational data protection was actually improved substantially because video material in which people appear only has to be viewed in unequivocally justifiable cases. If it should become unavoidable, the recorded image material is usable as evidence in court, and is approved for use by the works council and the data protection officer in a semi-automated process.

‘Made in Germany’ is generally an important feature for Dallmeier – you even conducted a survey on the subject. What advantages does this offer, both for installers and end customers as well?

Dieter Dallmeier: According to the survey we carried out in our end customer and installer community, fully 86% of those surveyed consider that, against the background of the coronavirus crisis, ‘Made in Germany’ or ‘Made in Europe’ are more important as criteria for purchase decisions than before. But this trend was clearly defined even before the crisis. In essence, there are three factors involved: firstly, more and more ethical questions are being raised in the public arenas of many countries about the origin of technologies. And this increasingly concerns not only the public sector. Secondly, legal and technological consistency is important. When entire product ranges of manufacturers are no longer approved for conformity testing by ONVIF for political reasons, for example. This naturally has extremely serious consequences for the businesses of the installers and end customers if – as happened recently – manufacturers of VMS systems no longer support the technical integration of cameras. And the third point – the most important in our experience – is the subject of security of course. And on this point, we have always placed the highest priority on ensuring that 90% of development and manufacturing is carried out in Germany and our commitment to the greatest possible manufacturing level. We consider it particularly important that we do not follow either OEM or ODM models. For the customer, this means that every line of software – and typically this is where security loopholes exist – originates from Dallmeier and consequently undergoes our strict quality controls with external penetration tests, etc. In addition, all our products feature extensive technical security and privacy functions, and thus comply to the highest degree with the guidelines of ‘Privacy by Design’ and ‘Security by Design’ as set forth in the GDPR.

In general, do you consider in-house development to be the best way for your company to develop new ideas and products?

Dieter Dallmeier: Yes, as ever! As long ago as 1992, the first video sensor with digital recording served as the most convincing proof that developing and manufacturing high-quality products in Germany pays dividends, even though we were laughed at back then. The Dallmeier group was built on the strength of just one product, the digital recorder, until 2004. In 2004 we began to develop the first Dallmeier IP camera, and today we own a patented camera technology which is unique in the world. None of that would have been possible if we had not collected expertise from the most varied range of industries over many years, and most importantly retained it in the company as well. It is thanks to the enthusiasm and commitment of my employees that we have been able to make these products. We stand for Made in Germany, and we will do everything we can to continue developing and manufacturing the best and the most secure video security technology products at our headquarters in Regensburg.

On the subject of openness: Dallmeier cameras can also be integrated into third-party systems...

Dieter Dallmeier: We have been members of ONVIF for a long time, and we have supported the standard in our cameras and recorders ever since it was formulated. This means that we can be integrated into any third-party system that supports the ONVIF standard. Even if, regrettably, misleading information to the contrary is being circulated. For example, we recently integrated Panomera successfully into the Genetec Security Center. We live our own philosophy here with regard to our customers as well: open systems and no dependencies. When special, optional features are required, we work closely with third-party providers and offer them our support.

Mr Dallmeier, the coronavirus crisis has affected different companies and industries very differently. How are you managing in this time – and how do you see the immediate and medium-term future?

Dieter Dallmeier: These are difficult times, and very few companies will survive this period without making some cuts. We have established a good reputation for ourselves in many industries all over the world. Casinos, stadiums, airports, municipalities, industrial corporations and many other sectors rely on our products, and we are already seeing an upswing in activities. The crisis also showed us how correct our strategy of keeping development and manufacturing in Germany was, and is. For the time being, we can only keep doing what we do well: work on new ideas and products, and move forward calmly, relying on our experience from the last 35 years.

most read

Is Your Venue Ready for Martyn’s Law?

Martyn’s Law demands stronger security by 2027. Is your venue prepared to protect and respond?

GIT SECURITY AWARD 2026 - The winners have been announced!

GIT SECURITY AWARD 2026: The best safety and security solutions of the year - now an overview of all winners

Safety and Security in an Emergency: How companies take responsibility with strategic personal protection and amok prevention

Personal protection & amok prevention: strategic concepts, training & responsibility for corporate safety and security

Airbus Defence and Space: Security as a strategic pillar of Europe's defense capability

Airbus Defence and Space protects sites, technologies and employees with modern security and cyber solutions - strengthening Europe's resilience in uncertain times

Between War and Peace: Hybrid Attacks and Their Impact on Critical Infrastructure

FOCUS TOPIC GERMANY - Hybrid attacks and drones: Security risks for Germany, its companies and critical infrastructure.