Sick AG: How EU Directives relate to Machine Safety – Part 3

Sick AG: How EU Directives relate to Machine Safety - Part 3. Those who design, construct or bring into circulation machines in the European Union must comply with the applicable s...

Sick AG: How EU Directives relate to Machine Safety - Part 3. Those who design, construct or bring into circulation machines in the European Union must comply with the applicable single market directives – above all, the Machine Directive. But take care: even if the correct safety and protective measures have been selected during planning and construction, many machines carrying the CE label have been put onto the market improperly, because they have technical safety defects such as insufficient safety distances or incorrect integration in the controller.

After the first two articles of this series looked at machine safety from the legal and standards points of view, this article is dedicated to describing the concrete implementation of safety during the planning, construction and operation of a machine. In addition, producers and users will be shown where and why even a safely constructed and equipped machine may be carrying the CE label without entitlement. This is not to say that this is due to any deliberate action, more a result of uncertainty.

Hazard Analysis Allows Safe Construction

The earlier the potential risks of a machine are detected, the more economically they can be neutralised. Thus, according to the Machine Directive, every producer has a duty to carry out a hazard analysis for their machine and, moreover, if the producer wants to conform to the Directive this must already be carried out during the planning, development or construction phases.

If the hazard analysis is not carried out at this early stage, hazards can remain undetected and risks underestimated. A further argument for an early hazard analysis is that any necessary protective measures undertaken at a later stage may sometimes only be capable of partial implementation, and almost always involve higher costs. Finally, the hazard analysis represents an important component of the EU Declaration of Conformity: machines without hazard analyses may not carry the CE label.

And if, despite this, they are indeed so labelled, then the producer or person bringing the machine into circulation is breaking the law – with all the potential product liability, and personal, consequences involved. Accidents can lead to claims for compensation. Incidentally, users who act like producers – by producing machines for their own use, utilising machines in a chain, or completing or modifying machines in such a way as to fundamentally alter them – are also considered to have the same status as producers or persons bringing the machine into circulation. They, too, must fulfil the basic demand for hazard analyses on the path to CE-certification.

Scope of the Hazard Analysis

The lifetime of a machine, which often lasts many years, can generally be divided up into the production, transport & commissioning, operation, decommissioning and dismantling phases. In order to meet the protective aims of the Machine Directive, the hazard analysis must therefore take all the life phases of a machine into account. Furthermore, the risks for each phase during proper use, as well as during predictable misuse, inattention or other incorrect behaviour by the operator, must be analysed – because most accidents do not take place during normal operation, but during cleaning, equipping, maintenance or repair work.

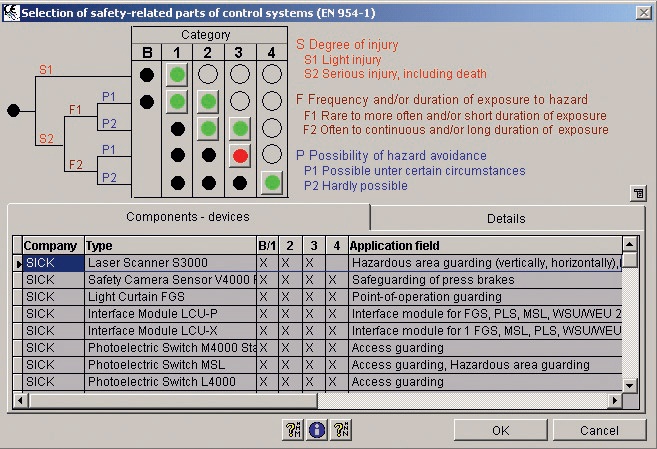

First the hazardous points-of-operation and areas of the actual machine or plant that present any risk of injury or illness to a person are determined. After identifying the potential dangers there is a risk assessment and evaluation, on the basis of which a safety concept with suitable protective and safety measures is derived – taking into account the particular technical requirements regarding production.

If the hazard analysis indicates that a machine poses no danger during any phase of its lifetime and with any kind of use, or it turns out that all the risks can be reduced or completely ruled out by means of constructional measures, the inclusion of information in the operating instructions and references to any potential residual risk are generally sufficient to ensure safe use of a machine.

If, however, there are hazards that cannot be reduced via the constructional route it will be necessary to use protective equipment – which, on the basis of the hazard analysis, one can now take into account early in the development of the machine.

Protective Equipment: Mechanical Separation or Non-contact Protection?

Once a machine’s potential hazards have been determined, the risks evaluated and the protective aims defined (ideally within the framework of a safety concept), the protective measures most suitable in terms of both operation and safety are selected. They must act reliably, must not impair the fundamental functional capability and operability of a machine or plant, and must be protected as dependably as possible against tampering or circumvention.

When selecting the safety technology to be used, constructors or producers can choose between separating protective equipment (fences, gates, etc.) and non-contact, electro-sensitive protective equipment (ESPE), whereby a combination of the two may be suitable depending on the machine or plant.

Separating Protective Equipment

There are two types of separating protective equipment: fixed, e.g. fences, and movable, e.g. gates. The latter are divided up into locked with and without magnetic release. Those with magnetic release offer the advantage that they can only be opened during a hazard-free state. In general, separating protective equipment must be designed to be sufficiently stable and durable.

This separating protective equipment is the first choice if parts can be ejected from the machine at high speed, when high pressures or radiation are involved, or when the plant or machine is very loud.

Separating protective equipment with magnetic release is necessary, in particular, for machines with longer stoptimes. When using separating protective equipment without magnetic release a safety distance, depending on the machine stoptime, must be taken into account. The cost factor must also be considered: in many individual cases, mechanical barriers are a more economical solution, particularly if little space is available and access to the hazardous area is only seldom, or even never, required.

Electro-sensitive Protective Equipment

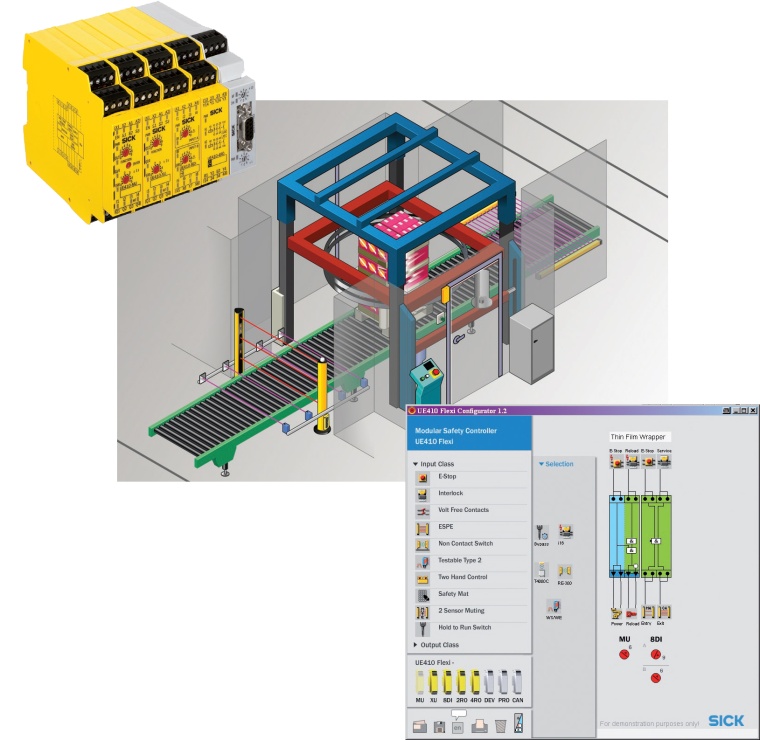

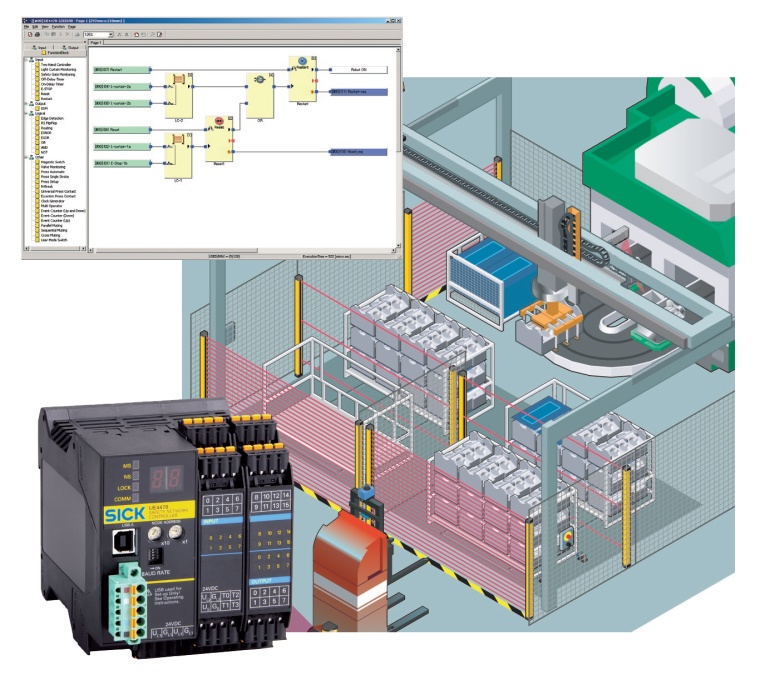

In all other cases, electro-sensitive protective equipment (laser scanners, light curtains or multiple light beam safety devices) for protecting hazardous points-of-operation, areas or access offer considerable advantages regarding flexibility, productivity and ergonomy. As long as there is a sufficient safety distance to the hazardous movement, the compact devices can be installed directly on the machine, or at the start of the hazardous area.

Access times are substantially reduced because the operator does not have to wait for a mechanical protective system to open. This, in turn, increases machine productivity, as feed or removal time is saved. Moreover, an intelligent integration in the controller permits a further increase in productivity, for example with two-cycle operation.

Furthermore, access to the machine for re-equipping is considerably simplified. Protective field heights and geometries can be flexibly defined with electro-sensitive protective equipment, and modified according to the system and application.

In addition, material flows into safety-relevant areas can be automated with electro-sensitive protective equipment and plants chained, as these devices are capable of distinguishing between persons and materials or pallets. As a result, automobile shells, for example, can be transported through safety light curtains from one robot to the next without impairing the protective function.

Inspection comes after Integration

The protective measure to be integrated on the basis of the hazard analysis ultimately depends on numerous factors. Of decisive importance during selection, is that the protective aims are achieved while meeting safety technology, production technology and operational technology aims. In order to ensure that this is the case in operational practice, the machine must be inspected after completion to check whether the protective measures are not only present, but are also effective.

In addition to carrying out the inspection, it is recommended that the test results and test comments are documented on a special form, and that these are added to the machine’s technical documentation. This also applies for warnings about any potential residual risks – that the Machine Directive stipulates should be part of the user information.

Residual Risks: Assistance from Informative User Documentation

Protective systems that are oriented upon the results of the hazard analysis can considerably reduce risks during operation of the machine, though often not completely eliminate them. Such remaining residual risks occur if there are technical or economic reasons, why complete operator protection is impossible to achieve, either constructionally or with safety equipment.

However, if a protective measure is not used, despite it being technically or economically possible, this is not a residual risk. Thus only “unavoidable” risks can be offset by informative user references, which include, among other things, appropriate information in the operating instructions, the description and definition of the residual risks, and recommendations regarding behaviour, equipment and qualification in the user information supplied, as well as the installation of warning signs and signals (warning lights, sirens, alarms) on the machine.

CE Present but Still Not “-Europe-compliant”

The hazard analysis, safety concept, standardcompliant construction and equipping of the machine, testing and documentation – now, one would think, the demands of the Directive have been met and the machine is ready for the CE label. Despite all this, however, a CE label and EU Declaration of Conformity are often no guarantee that a machine is without defects in safety technology terms.

There are often contraventions of the formal prerequisites - the first time a machine is brought into circulation and commissioned. Thus the fact that only machines that are “ready for use” can carry a CE label is often disregarded. If machines are not ready for use, compliance with the Directive must be achieved at the setting-up location, and all the prerequisites for proper use fulfilled.

The term “ready for use” includes the presence of operating instructions that conform to regulations. Further examples of non-compliance include: errors in the Declaration of Conformity or Producer’s Declaration, failure to carry out EU prototype testing; incomplete technical documentation, lack of consideration of the ergonomic principles demanded in the Machine Directive, and safety deficiencies determined in inspections during operation and in the immediate vicinity of machines.

Particularly in the latter case, the user is again responsible – and is liable if there are accidents – as a result of the EU User of Equipment Directive and works safety regulations.

Summary: Use the Standards, Go for Safety

In addition to the technical standards, producers (or those bringing machines into circulation) would be very well advised to also take into account the formal prerequisites during provision of the CE label. This advice is based not only on the responsibility for the operating safety of machines, but also on the legal consequences that non-conforming machines – or accidents during operation on such equipment – can have for companies, as well as individuals within companies.

Moreover, an intensification of market monitoring can be expected in various countries in coming years – for reasons of fair competition, among others. Users, for their part, should stipulate compliance with the relevant safety standards and directives as a guaranteed property in their orders.

After delivery, and before initial commissioning, the safety technology specialists working for the user of the machine should carry out technical safety inspections and report defects without delay.

The CE label only provides security when all the technical safety and formal demands necessary for the Declaration of Conformity have been fulfilled.

References:

- Rolf Reudenbach: Sichere Maschinen in Europa, Teil 2: Herstellung und Benutzung, Verlag Technik & Information, Bochum

- Rolf Reudenbach: Sichere Maschinen in Europa, Teil 3: Gefahrenanalyse, Verlag Technik & Information, Bochum

- Sick AG: Leitfaden Sichere Maschinen mit optoelektronischen Schutzeinrichtungen, Sick AG, Waldkirch

Contact:

Gerhard Dieterle and Simon Köpfer

Sick AG,

Waldkirch, Germany

Tel.: +49 7681 202 0

Fax: +49 7681 202 3863

info@sick.de

www.sick.com

most read

Assa Abloy's battery-powered Aperio KL100 secures lockers

Boost workplace security and operational flexibility by securing more than just doors.

Airbus Defence and Space: Security as a strategic pillar of Europe's defense capability

Airbus Defence and Space protects sites, technologies and employees with modern security and cyber solutions - strengthening Europe's resilience in uncertain times

GIT SECURITY AWARD 2026 - The winners have been announced!

GIT SECURITY AWARD 2026: The best safety and security solutions of the year - now an overview of all winners

Is Your Venue Ready for Martyn’s Law?

Martyn’s Law demands stronger security by 2027. Is your venue prepared to protect and respond?

Integrated and Futureproof: Traka’s Next Chapter

Interview with Stefni Oliver on Traka’s Vision for the Future