There Is No Standard Solution for Lithium-Ion Batteries

The Wagner Group has developed a customized fire protection solution for Kettler Alu-Rad for their automated high-bay warehouse. The rechargeable lithium-ion batteries that are installed in e-bikes and stored prior to shipping present a big challenge because of the fire risk of their composition, a challenge met by Wagner Group with the help of extensive fire testing – and a combination of fire detection and fire prevention by oxygen reduction.

Under the pressure of global competition, no company can afford to lose any stock or be put out of operation for any length of time. Fires, and their consequences, must be avoided at all costs, which makes a reliable fire protection system essential, and especially where there are high-risk goods stored.

Warehouse with Up To 50,000 E-Bikes

Storing lithium-ion batteries presents a particular problem for warehouse fire protection because they are at risk of spontaneously catching fire on their own, which can have fatal commercial consequences as well as endangering the environment: Once into thermal runaway, they cannot be extinguished with water; dangerous substances are released, and if the fire spreads to adjacent goods, a chain reaction leads to a rapid spread of fire in the warehouse. The search was on for a fire protection system for the fully automatic high-bay warehouse of Kettler Alu-Rad in which up to 50,000 e-bikes with built-in rechargeable batteries are packed and ready for dispatch, so that any spread of a thermal runaway fire would be suppressed.

Compact Storage of Lithium-Ion Batteries and High Ceilings

There is currently no ‘standard fire protection solution’ when storing lithium-ion batteries. The inherent potential of this form of energy storage to self-ignite cannot really be countered and, if there is a fire, conventional types of extinguishant are not sufficiently effective. At their new and modern production facility, the bicycle manufacturer, together with the specialists from Wagner Group and the client’s insurance company, set about defining specific fire protection goals for the high-bay warehouse.

The lithium-ion batteries in the e-bikes are of varying sizes and capacities. They are charged to around 30 % and are thereby a particular fire risk – a real challenge with special requirements for the fire protection system. The compact storage in the high-ceiling warehouse, the packaging material of the goods as well as the potential risk of the electrically-driven automatic storage system all influence and extend the potential amount of damage. The most important goal was therefore to confine any thermal runaway to the one bike and prevent the spread of fire.

Extensive Fire Testing: Oxygen Reducing System

The ideal method of storage of e-bikes was established through extensive fire tests. They were carried out at the DMT Test Laboratory for Fire Protection, a fire testing center complying with DIN EN ISO 9001 and accredited to DIN EN ISO/IEC 17025:2005. The significant difference of the solution conceived for Kettler is that storage is possible in a normal warehouse environment, without the batteries having to be kept in special containers as with other dangerous goods and materials. This greatly minimizes the space requirements as well as the number of staff required and also simplifies the logistics. To achieve this, the OxyReduct oxygen reducing system is used. It lowers the oxygen content to a pre-defined level within the protected area of the high-bay warehouse and maintains it at this level. This stops the spread of fire if a battery catches alight; a chain reaction can be prevented by the ideal spacing of the boxes in storage that was determined in the tests. Business continuity is ensured and deliveries can also continue to be made. The automatic warehouse can be entered under the conditions given by DGUV recommendations.

In order to detect smouldering and cable fires in good time, which are still possible even in the oxygen-reduced atmosphere, Wagner supplements the solution with the highly sensitive, deception-proof Titanus early fire detection system. Aspirating smoke detectors react up to 2,000 times more sensitive than conventional point detectors and detect fires during the early pyrolysis phase. They continually take samples of the air in the surroundings and check them for smoke particles. An appropriate response can be made in good time by detecting a fire at this early stage.

This is an article of our jubilee issue. Click on the button to find all of the interviews, articles and the e-paper.

OxyReduct: Oxygen Reduction System Explained

The statistics show that a fire breaks out every two minutes somewhere in Germany, and often causes significant damage. No matter whether it is a warehouse, a computer center or storage facility, all commercial operations are dependent upon absolutely reliable fire protection. No company can afford business interruptions and so, besides protecting people and high-value (or even irreplaceable) goods, business continuity has the highest priority in the case of a fire.

Wagner Group has the appropriate fire protection solutions in its portfolio to meet this requirement: the VdS-recognized OxyReduct fire prevention system. Traditional fire protection systems are passive, which means that they only react when a fire has already started. The preventive OxyReduct oxygen reduction system however gets into action before a fire starts and thereby actively provides a high level of safety. Consequential damage, such as that caused by water, foam or other extinguishants, is prevented – and dangerous substances that can be released during a fire are also avoided.

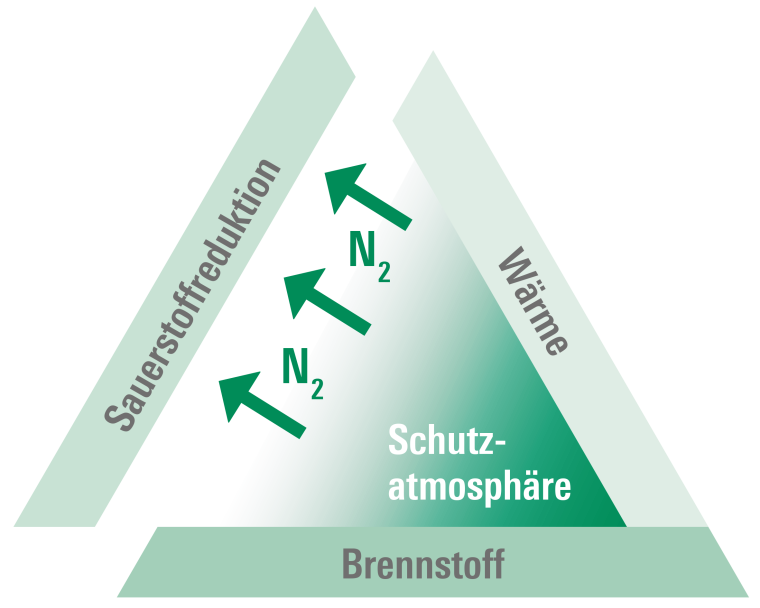

The Wagner Group’s certified OxyReduct fire prevention system preventively ensures that under specific conditions a potential fire cannot even start or spread. By introducing nitrogen into the protected area, the oxygen concentration is reduced to such a level that the specific inflammation level of the material present is not reached. OxyReduct thereby creates an atmosphere in which under defined conditions the eruption of flames is impossible. The remaining oxygen is not sufficient to maintain a fire or to let it spread.

The required nitrogen is supplied by the system directly from the surrounding atmosphere. Nitrogen is a fundamental element of our natural atmosphere and this saves the cost of transport, and a lot of space too, while conventional firefighting systems require large areas to store the extinguishant, large water tanks for a sprinkler system for example, OxyReduct only requires a space of only a few square meters.

Related Article:

Interview with Dirk Band, Director Sales at Wagner Group, about the special fire risks of lithium-ion batteries and effective protection methods

This is an article of our jubilee issue. Click on the button to find all of the interviews, articles and the e-paper.

most read

When the Internet stumbles: Why DNS is important

When DNS fails, the internet stumbles-AWS outage proves resilience and redundancy are vital for digital trust

GIT SECURITY AWARD 2026 - The winners have been announced!

GIT SECURITY AWARD 2026: The best safety and security solutions of the year - now an overview of all winners

Safety and Security in an Emergency: How companies take responsibility with strategic personal protection and amok prevention

Personal protection & amok prevention: strategic concepts, training & responsibility for corporate safety and security

Airbus Defence and Space: Security as a strategic pillar of Europe's defense capability

Airbus Defence and Space protects sites, technologies and employees with modern security and cyber solutions - strengthening Europe's resilience in uncertain times