The railways are becoming increasingly important as an efficient and sustainable transportation solution in light of challenges posed by climate change and traffic congestion. In spite of the COVID hit, rail passenger transport has been increasing for years and is a central pillar of the desired transport mix across Europe. Reliable fire protection is essential for the optimum safety of passengers and rail vehicles.

According to the German Allianz pro Schiene eV, an association of 16 nonprofit organisations and 29 commercial enterprises, rail is by far the safest means of transport. In order to ensure the safety of passengers, trains and infrastructure, adequate fire protection measures are an important and indispensable aspect of rail traffic management.

Fortunately, fires on trains are rare – but when they do occur, they can endanger human life and cause major economic and ecological damage. Heat, smoke and flames themselves can maim and even kill, as can panic reactions by passengers caught in the fire.

Fire Protection Prevents Damage

Fires endanger human lives, cause material damage to trains and infrastructure, disruption to operations and can provoke significant environmental damage. Fire protection solutions that aim to prevent or quickly extinguish fires are therefore crucial for passenger and rail vehicle safety, and for protecting the environment.

Dr Markus Müller, Managing Director of Wagner Rail, says: “If we want to promote the safety of passengers, rail vehicles and rail infrastructure, manufacturers and operators of rail vehicles must focus on holistic fire protection solutions. We are doing everything we can to improve rail safety. Detecting fires as early as possible is one of the keys to our success.”

Wagner offers holistic fire protection solutions designed to ensure the safety of people travelling by rail, including aspirating smoke detectors (ASDs), which have been deployed on trains for over 30 years.

Effective and Reliable Fire Detection

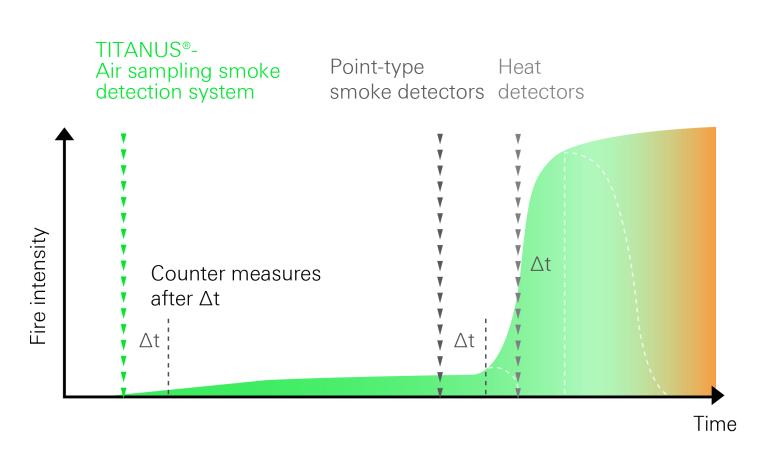

Identifying potential fire hazards and detecting fires as soon as they occur allows emergency services to evacuate, and put the fire out as quickly as possible.

Dr Müller says: “Reliable and rapid fire detection is particularly important on trains for two reasons: firstly, to raise the alarm quickly and protect people in the event of an emergency; and secondly, to keep fire damage to the trains and the infrastructure to a minimum. We recommend our wide range of automatic detectors – ASDs, optical detectors or multi-sensor fire detectors – to monitor the protected areas for smoke as a fire indicator.

“State-of-the-art systems for spotting fires early detect smoke particles in the pyrolysis phase, ie, the early stage of a fire before open flames develop. For technical areas where smoke detection is unsuitable due to the ambient conditions on site, the temperature parameter is used as an alarm trigger. Here, we use linear or heat detectors, which can be integrated into the ring bus in combination with a fire alarm control panel (FACP) or used as a standalone solution.”

Protected from False Alarms

Especially when used in train passenger areas, detectors must be highly resistant to false alarms, so that unclean air, such as cigarette smoke from unauthorised smoking in toilets, does not trigger an alarm that causes unnecessary emergency stops.

For early fire detection in trains, ASDs are often the chosen solution. They continuously take air samples from the monitored area via a connected pipe system. Air filters remove foreign substances that are not required for fire detection. This precise and continuous monitoring of airflow enables the detection of even the finest fire smoke particles. Fire alarm control panels record the messages and issue alarm and status messages via the specified information media.

Three Decades of ASDs

Fire detection solutions with aspirating smoke detectors have been used for three decades to improve the safety of rail transport.

Dr Müller says: “Our records show ASDs being used in 1994 in locomotives in service in Switzerland, Scandinavia and India – and most of them are still in service today.

“ASDs marked Wagner’s entry into the railway market, and today our systems are mainly found in passenger compartments, control cabinets, supply, exhaust and recirculation air systems, underfloor areas, engine rooms and in air conditioning ducts. Today, our ASDs are highly resistant to false alarms, so that it does not lead to faulty and costly service interruptions. So it’s fitting to celebrate the 30th anniversary of fire protection with this technology.”

Titanus devices from Wagner offer further advantages. For a defined area, ie, a passenger carriage, only a single ASD is required. The heart of the system, consisting of pipes, a detector module and a filter, is located behind the ceiling or wall panels. Passengers can only discover the air sampling points, which are just a few millimetres in size, when they look very closely.

In contrast to the usual point detectors, they are protected against vandalism – as what is not visible and does not protrude as a mounted device is not exposed to vandalism and cannot be accidentally damaged.

Invisible Fire Detection

Train designers can discretely integrate the system into the existing interior design. They can choose the number and positioning of the air sampling points to suit each specific interior, ensuring optimum safety even when the airflow is affected by room elements or air conditioning systems.

Wagner Rail also offers smoke switches primarily for applications without a permanent presence of passengers and with only selective monitoring of individual objects, such as control cabinets, containers, and the driver’s cab. They provide a sensible alternative to ASDs as stand-alone solutions without the need for an FACP.

Water Mist Systems Protect People

Automatic fire extinguishing and firefighting systems are increasingly installed in addition to fire detection systems in response to operator demands and the latest industry standards and guidelines.

These are now typical in passenger compartments, sleeper or couchette cars and all staff areas. Water mist systems are deployed to limit the spread of a fire until the next available stop and contain the smoke so that passengers can escape to safety.

Dr Müller explains: “Our engineers developed special water mist systems, sprayed from small nozzles in very fine droplets, so that a large amount of energy can be absorbed with a small amount of water. The fine droplets also wash out the resulting smoke gases.”

This technology allows the water supply tanks to be adapted to the carriages, making optimum use of available space and eliminating the need for conventional pressure tanks or high-pressure lines. If a compressed air supply is available, it can be used to generate the water mist. Alternatively, the water mist system can be combined with the existing toilet tank to save space and weight.

To protect technical areas in containers on or under the train and in technical cabinets, today’s standards and guidelines require the installation of automatic extinguishing systems, depending on the fire risk. The aim is to extinguish a fire as soon as it starts. These systems are becoming increasingly important in commuter and metro trains as well as in underground trains.

Fire Protection for Technical Areas in Rail Vehicles

The Wagner portfolio has included gas extinguishing technology for many years, using natural extinguishing agents for sealed-off, closed areas, such as control and switch cabinets as well as electrical equipment in underfloor areas and locomotives.

Gas extinguishing systems introduce natural extinguishing gases, such as nitrogen, into the protected area, reducing the oxygen concentration and so extinguishing all types of fires by depriving them of the ‘air to breathe’. They are modular and can easily be adapted to the size of the areas being protected. Combined with a fast and reliable fire detection system, the use of gas extinguishing technology allows an incipient fire to be safely extinguished without leaving any residue. This prevents the extinguishing agent from becoming a hazard to electrical systems.

Energy-independent extinguishing systems are also in use. These autonomous, stand-alone systems are connected directly to the train control management system (TCMS). They are an effective solution for new trains and potentially for retrofit in existing vehicles. These autonomous fire protection systems are in all types of rail vehicles, such as trams, light rail vehicles and elevated trains, high-speed trains, passenger coaches and people movers.

Aerosol Solution for Effective Extinguishing

Technical areas such as transformers, power converters or diesel engines are often equipped with several non-closable openings for ventilation. The motion of the train creates air currents in these areas, making it difficult to extinguish the fire.

Normally, the train has to slow down or stop completely in order to extinguish the fire safely – with corresponding consequences for rail logistics.

As an important milestone in railroad safety, Wagner Rail has introduced an aerosol system to meet this challenge. It is used where gas extinguishing systems with containers in the housing are too complex or openings in the protected areas are too large for reliable extinguishing using gas.

The aerosol extinguishing system contains a defined quantity of extinguishing agent in a cartridge. The system initiates the extinguishing process when electrically activated after a fire alarm or by self-activation at a temperature of 300oC.

The controlled burning of the extinguishing agent in the generator creates aerosols that flow out into the protected area. The extinguishing effect is based on the interaction of the flames with the aerosol: the chemical extinguishing effect can intervene in the chain reaction of the fire and interrupt the combustion process. At the same time, the physical extinguishing effect cools the source of the fire. In this way, a fire can be safely extinguished in a confined area. The flooding of the extinguishing area is practically pressureless, so that no special pressure relief measures are required.

Wagner did extensive prior research in cooperation with German technical inspection association Tüv Süd Rail and in compliance with the German ARGE Guideline Part 2 ‘Firefighting in railway vehicles’.

They carried out tests with fire scenarios under various ventilation situations to perfect the technology. They successfully extinguished fires completely in ventilated technical rooms even while the train was exceeding speeds of 100kmh using aerosol extinguishing agent cartridges.

Passenger Safety Around the World

FACPs issue fire protection messages and controls, such as raising the alarm, triggering extinguishing or controlling things like selectively switching off the air conditioning or closing fire doors. All fire detectors and other devices are connected to the FACP via a ring bus. This ensures that if a wire breaks, all devices are still connected to the control panel and none will fail. The integrated ethernet connection allows the FACPs to be connected to the train bus interfaces.

Passenger safety is a top priority around the world. This is why manufacturers and operators of rail vehicles rely on high-quality, reliable and efficient systems. Wagner fire protection systems are fitted in countries from A-Z worldwide, on tourist attractions, on mountains and in deserts.

Dr Müller says: “We have so many exciting projects that it is difficult to single out individual ones; but I call to mind the world record train in Switzerland, our projects in India with no less than 5,000 cars, the Transrapid in Shanghai, the Talgo highspeed train for Saudi Arabia, the Caltrain in the USA, the BB Railjet in Austria and even cable cars like the Wurzeralmbahn, which takes skiers and hikers safely up the mountain to an altitude of 1,400 metres.”