Automated Parcel Tracking Secures Transport Logistics at DPD

DPD, with over 7,500 employees and one of the leading parcel and express couriers in Germany, has taken up the cause of guaranteeing its customers high reliability and efficiency. ...

DPD, with over 7,500 employees and one of the leading parcel and express couriers in Germany, has taken up the cause of guaranteeing its customers high reliability and efficiency. In addition to a comprehensive European network and strong local partners in international dispatch, the most modern technology now provides the basis for perfect transport solutions, even for highly complex tasks. Modern video technology and the use of intelligent software help the company to minimize complaints and to optimize processes in the Münster DPD Depot.

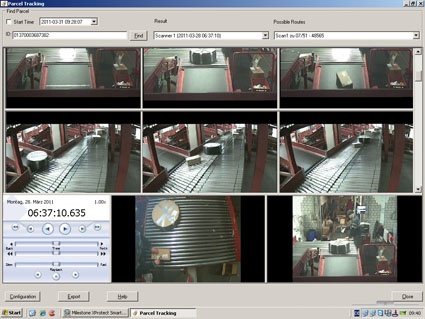

DPD provides its customers with an online parcel tracking facility with which the customer can check on the current dispatch status at any time by entering the parcel number or reference number. Registered customers can use other services such as online delivery notification or funds transmission for COD deliveries. But DPD also uses parcel tracking for the organization and securing its parcel depots, using an IP-based video surveillance system at its depot in Münster that was conceived and implemented by the System Integrator Heiko Viehweger (now Mavi-sec Sicherheit). At the heart of the system is the Milestone XProtect Enterprise video management software that was integrated with a special Parcel Tracking plug-in by Mavi-sec and adapted to the needs of DPD.

Following the Parcels Inconspicuously

The requirement from DPD was clear right from the beginning: parcels must be able to be followed with the help of a video surveillance system throughout the storage and logistics areas of the Münster parcel depot. The system integrator, Heiko Viehweger, is a specialist who, together with his colleague Michael Marwinski, not only possess many years of experience as integrators and commissioners of security systems but also have the know-how for security and logistics in service industries.

After carrying out an analysis of the transport routes and interfaces for the parcel logistics and taking stock of the existing technology, a system specification was first created, followed bya user layout for the system. In close cooperation with the software developers from Milestone, a special plug-in for the parcel tracking was programmed with the help of the analysis and on the basis of the Milestone XProtect Enterprise open video management software.

Completely Monitored from Goods Inwards to Handover

The installed video surveillance system follows and documents the flow of goods from the intake area right up to handover to the delivery drivers that accept the parcels for their delivery area. The goods can be located at any time via the video management software, even through complex logistics chains.

After arriving, all parcels are identified by manual and automatic scanning of their bar code and the parcel note number and simultaneously linked with a video image. This is handled by the XProtect Transact module of the software. This documentation can already be useful for the operator when it comes to questions on who is responsible for damage before the parcel reached the DPD Depot. Cases of damage, such as leaking fluids for example, can thus be better judged and investigated on the basis of the documented video images. Depending on the destination or the postal code, the parcels then go through a complex system of conveyor belts that ultimately transport them to their point of handover. Along their way through the sorting channels, the parcels are automatically tracked with the help of 79 video cameras and the images are archived.

Analog cameras, some of them vandalism-protected or dust proof, with VGA definition (550 TVL) are sufficient for this type of surveillance in Münster, although megapixel cameras are being considered for future projects. The parcels are scanned once more at the point of handover before being loaded, when the liability is thereby given to the delivery agent. The handover is documented by the scan procedure and the video images.

Nothing Gets Lost

The DPD parcel depot in Münster continuously runs an analysis of the incoming parcels and the goods handed over, and this provides an overview of the shipments that have arrived but not been passed on. If these parcels are subsequently shipped within a certain timeframe (for example, after a blockage or following an intermediate check), the case is closed and this is also documented. In the rare cases that parcels are logged as "missing" after an analysis by the system, the software allows a quick check of exactly where the parcel went missing along the way. This procedure is so important for DPD because the company proactively goes through the procedures when there are problems and can use the video documentation proactively before there are possible complaints a few days later.

Entering the parcel note number of the missing shipment in the software menu provides the most recent information about the last scanning point. The intended destination and the probable route for a parcel going to this postal district can then be chosen. The software with the parcel tracking plug-in then automatically delivers timed portions of the requested video sequences at the monitored station along the route. The timed intervals were programmed in advance, in accordance with the passage time of a route, and time buffers can also be programmed for safety. The video data of such a search can be easily extracted using the software, and forwarded to the security department or an employee who handles complaints.

Summary

For DPD, the installation of the system provides obvious advantages: on the one hand the company demonstrates its power of innovation and competence in security, in particular to demanding customers. Manufacturers, providers of high-value electronic products and pharmaceutical companies are increasingly carrying out inspections and audits, awarding shipping contracts to a parcel service who satisfy them that quality control measures are in place. Continuous optimization of the logistics systems also helps to process complaints from end users about missing or incomplete deliveries and minimizes the effort required for subsequent investigation (e.g. where were the goods damaged?).

A perfect system? Nearly, although thought is already being given to improving the quality of video recordings in future projects by using megapixel IP cameras so that address labels and parcel numbers are readable. Heiko Viehweger says: "We were able to introduce our system in the DPD Münster depot and to adapt the system to meet the local requirements thanks to close collaboration with those responsible at DPD and the software developers from Milestone. Further development and adaptation of the system by us for the whole logistics industry is therefore quite possible."

Business Partner

MaVi- sec Sicherheit GmbHBrauereistr. 16

46499 Hamminkeln

Germany

most read

Safety and Security in an Emergency: How companies take responsibility with strategic personal protection and amok prevention

Personal protection & amok prevention: strategic concepts, training & responsibility for corporate safety and security

Training at Fraunhofer SIT: Strengthening resilience against cyber attacks

Knowledge in cyber security is evolving rapidly - continuous training is therefore important.

Integrated and Futureproof: Traka’s Next Chapter

Interview with Stefni Oliver on Traka’s Vision for the Future

When the Internet stumbles: Why DNS is important

When DNS fails, the internet stumbles-AWS outage proves resilience and redundancy are vital for digital trust