Honeywell Analytics: “Definite Shift towards IR”

Honeywell Analytics: "Definite Shift towards IR". Gas detection has been through many evolutions since the birth of the technology over 50 years ago. A major milestone in its histo...

Honeywell Analytics: "Definite Shift towards IR". Gas detection has been through many evolutions since the birth of the technology over 50 years ago. A major milestone in its history has been the introduction of infrared optical (IR) detection. Gases absorb infrared light at specific wavelengths and IR technology allows for the identification of these gases by measuring the absorption of light at these wavelengths.

IR based devices can be “tuned” to recognise specific gases by only analysing the particular band of wavelength for that gas. IR technologies use either lamps or hot bodies or lasers and as technologies have evolved to become more sensitive, devices have moved from lamps towards solid state sources. The use of lasers permits narrower band detection (known as FLS, Fine Line Spectroscopy), allowing for enhanced sensitivity by using a concentrated beam of light.

This is necessary for the detection of certain gases, particularly toxic gases like H2S with minimal crossinterference.

Infrared Technologies – a Brief History

Since the conception of IR in the late 1970s, a variety of principles have developed. One that has been prevalent for the last 20 years is NDIR (Non-dispersive Infrared), which is typically fairly broadband and can be used for Point or Open Path detectors. In fact one of the first products on the market using this technology was the 5050, produced by Sieger (now known as Honeywell Analytics), in 1986. With this type of IR detection, a gas is pumped or is allowed to diffuse into a sample chamber (or light tube) where it crosses a beam of infrared light from a lamp. The gas is then measured electro-optically by its absorption of specific wavelengths in the IR spectrum and the gas is directed through the chamber towards the detector.

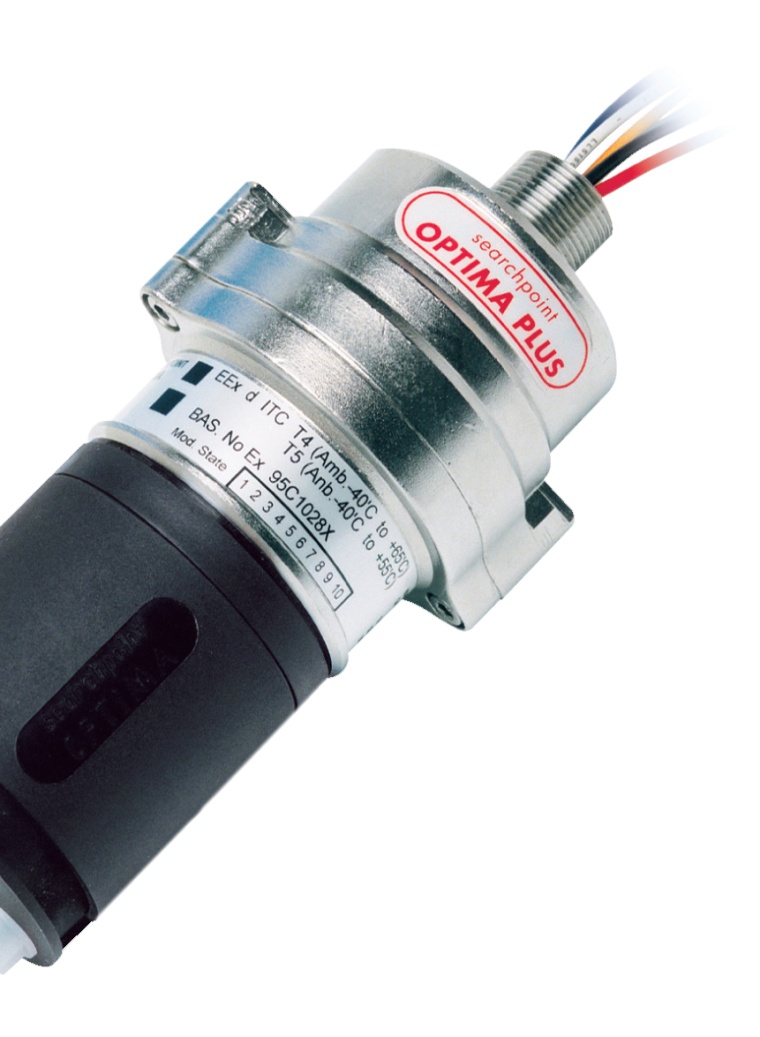

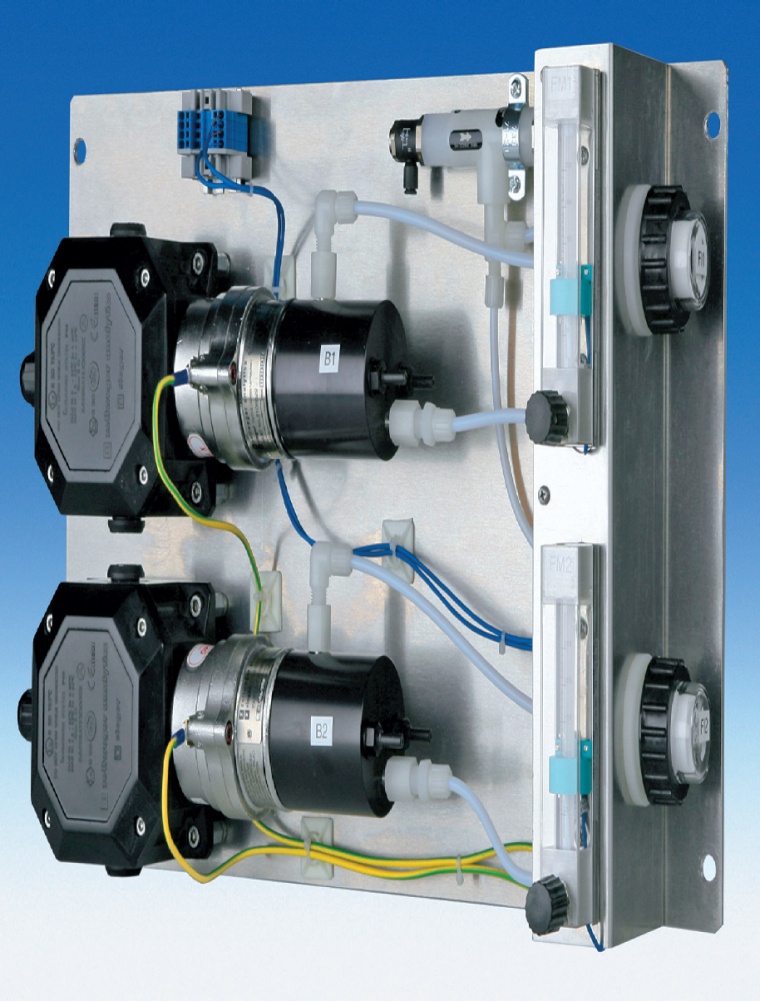

There is an optical filter in front of the detector that eliminates all light except the specific wavelength that the selected gas molecule can absorb and this wavelength is compared to a reference wavelength. An example of an IR point detector is the market-leading Searchpoint Optima Plus from Honeywell Analytics. Due to its construction, this device is ideally suited for use in Sampling System applications either with an injector or a pump.

Honeywell Analytics advanced design uses two sources and two detectors each individually filtered in a fully compensated design that handles source and detector drifts. This is not true of all available IR Point detectors and some can be prone to drift of either and consequently error and potentially false alarm. The next major milestone in IR has been the development of Open Path IR technologies; a principle that allows gas to be dynamically detected across a large range thus improving the chance of detecting a gas leak.

This type of system uses a transmitter and receiver configuration where a beam of IR light is sent from the transmitter to the receiver. Any gas that crosses the beam absorbs some of the light at a specific wavelength and the difference in light intensity is measured and compared to a reference wavelength. In fact Sieger (now known as Honeywell Analytics), worked in partnership with a large oil company to produce one of the first open path flammable gas detectors.

The commercially available version, known as the Searchline, was launched in 1988 and was the first hazardous area certified Open Path detector on the market. In line with the company’s strong legacy of optical innovation and continuous improvement, the latest generation product, the Searchline Excel, is the current market-leading Open Path product.

A principle that has some similarities to Open Path, in the fact that it monitors over large dynamic range, is LIDAR (Light Detection and Ranging); an optical remote sensing technology that measures the properties of scattered light to detect not only the presence of gas, but determine where in the range it is present. This is achieved by using laser pulses (similar to radar technologies that use radio wave pulses), measuring the time delay between transmission of a pulse and the detection of its reflected signal.

LIDAR (also known as ALSM; Airborne Laser Swath Mapping), is very expensive and is used mostly in laboratory environments and in atmospheric physics.

Peter Harrie, Marketing Manager for Fixed Premium Products (EMEAI – Europe, Middle East, Africa, India) for Honeywell Analytics, comments on the evolution of IR technologies. “As the most advanced detection principle used in commercial gas detection systems, IR has developed over the last 10 years with a trend towards designing devices that use lasers rather than lamps where lower levels of detection are demanded, providing enhanced sensitivity and performance. The trend also continues from Point Detection to a mix of Point and Open Path. The greatest current challenge is the delivery of an Open Path toxic gas detection system that has the sensitivity needed to detect gases like H2S with minimal cross interference. As the world’s leading optical technologies specialist, this is an area in which Honeywell Analytics has been heavily involved. As the manufacturers of Searchline Excel, the current market-leading Open Path flammable gas detector, we have employed our expertise and knowledge to develop a device that uses Fine Line Spectroscopy to deliver the same unrivalled performance as Excel, but for the detection of H2S at ppm levels. This revolutionary product will be launching later this year.”

IR Gas Detection – What Are the Benefits?

There are a number of reasons why IR devices are becoming more popular. In fact no other detection principle offers the same level of benefits, as Peter Harrie explains. “IR gas detection systems can be either Point or Open Path and there are a number of common benefits to these types of system; they offer a fast speed of response (typically T90 in 1–3 seconds for an Open Path system), they are immune to being poisoned (unlike catalytic beads that can be poisoned by compounds like silicone) and work in inert atmospheres. There are no filters to get blocked, which could potentially stop gas getting to the sensing elements. With the expertise of a company like Honeywell Analytics behind them, they can be developed to work in adverse weather conditions such as fog, snow, rain and sunlight. They have a long operating life and require less maintenance than other systems. In addition to these common benefits, an Open Path system also provides a better chance of seeing gas because it monitors over a wide area simultaneously (up to 200 m). And Honeywell Analytics IR detectors perform certain selfchecking diagnostics to ensure it they are always able to ‘see gas’ and provide an early warning of a need for maintenance. They are thus fail-safe with no unforeseen failure modes. Another key benefit from Open Path is reduced wiring costs because of its ability to monitor a wide area with a single transmitter and receiver set-up, where many points would be needed to provide the same coverage and level of protection.”

Market Place Trends

As we move towards the latest revolution in IR gas detection; the release of a reliable system designed for the detection of low-level toxic gases, IR is becoming more prevalent in a wide range of applications. Historically the gas detection market is conservative regarding new technology and, some 30 years since its conception, it is only now that we are seeing a major trend towards IR Point and Open Path systems.

As a Strategic Marketing Manager for Premium Fixed Products, Peter Harrie has an intimate knowledge of the market place and comments on the trends regarding IR gas detection usage. “We are continuing to see a definite shift in the market towards IR devices and a mix of Point and Open Path. Many sites that have traditionally used catalytic beads are changing their systems to Point IR, whilst sites that have traditionally used point IR are now integrating Open Path to include a mix of both. There are a number of reasons for this. As previously mentioned, IR provides a number of tangible benefits but there is also a drive within the market to reduce ongoing maintenance costs; businesses are now thinking in terms of whole product life, taking into account reduced need for maintenance and the addition of self-checking diagnostics that assist planned maintenance. Another key driver has been the online availability of devices; for example, an Open Path system is able to ‘know’ if it is online and able to see gas due to the constant communication between transmitter and receiver. This is particularly important when it comes to SIL (Safety Integrity Level) ratings, which more and more businesses are now demanding. The Oil, Gas and Petrochemical industries were the first to adopt IR devices but now a wide range of varied applications are seen as more businesses are shifting towards the use of IR based detection systems.”

Whatever the future holds for gas detection, it seems likely that IR technologies will remain at the forefront of innovation. And the movement towards Fine Line Spectroscopic technology will mean that future product generations have enhanced sensitivity and the ability to detect a wider range of gases including toxics at lower concentrations.

Gemma Bayless

Contact:

Alexander Zabawa

Honeywell Analytics

International Freephone: 00800 333 222 44

gasdetection@honeywell.com

www.honeywellanalytics.com

most read

Integrated and Futureproof: Traka’s Next Chapter

Interview with Stefni Oliver on Traka’s Vision for the Future

Airbus Defence and Space: Security as a strategic pillar of Europe's defense capability

Airbus Defence and Space protects sites, technologies and employees with modern security and cyber solutions - strengthening Europe's resilience in uncertain times

Training at Fraunhofer SIT: Strengthening resilience against cyber attacks

Knowledge in cyber security is evolving rapidly - continuous training is therefore important.

When the Internet stumbles: Why DNS is important

When DNS fails, the internet stumbles-AWS outage proves resilience and redundancy are vital for digital trust