Hard as Steel!

The latest production technologies are the focus for the steel giant ArcelorMittal, the world’s leading steel manufacturer.

Their aim is to make their own production processes safer and more efficient and that included optimizing the burner monitoring of the furnaces in their downpipe cold rolling mill in the Belgian city of Ghent. Efficient, safe automation should include more efficient diagnostics. When converting the plant, ArcelorMittal opted for the all-round service package from the automation expert Pilz: their automation system PSS 4000 is used but that’s not all – Pilz also assumed responsibility for implementing the conversion.

The cold rolling mill at ArcelorMittal in Ghent is used to refine steel coils (strip steel rolls) in accordance with customers’ requirements. The production process for downpipes in the cold rolling mill is divided into five steps in total: pickling, cold rolling, annealing, tempering and then finishing.

Production Conditions as Hard as Steel

Before pickling there is a hot rolling process, during which an oxide layer forms on the steel plates. This must then be removed in the cold rolling mill during pickling, before the steel plates can be further processed. In the next step, cold rolling, the pickled, hot-rolled plate is cooled and then reduced to its required thickness through pressure and tension forces.

The steel strip must first undergo heat treatment to enable it to be cold-formed. This process is carried out in two bell annealing areas – i.e. in annealing furnaces for steel coils, where the steel strip remains for a while in a closed furnace – and in a continuous annealing and refinement plant, which the steel coil passes through relatively quickly, in contrast to the closed annealing chamber. The steel coils that leave the bell annealing area are then tempered (special heat treatment for steel), improving the mechanical surface properties of the steel plate. In the final step the strip steel rolls are packaged and are then ready for shipping to the customer.

Yves De Sloover is an engineer at the cold rolling mill at ArcelorMittal: “Our department is responsible for maintaining the processes in this area. On the continuous annealing plant we also look after the PLC controller and the burner setting. Our aim is to keep production running continuously. That includes constant optimisation of the furnace.”

One problem was that the start-up burners that ignite the main burners frequently shut down, so this stage of the process was one area of focus for optimization. De Sloover explains: “At the start of the process the furnace is heated up to 1200 °C with an open flame. In total there are 50 main burners, which are fed by 30 start-up burners. When the temperature of the furnace drops below 760 °C after a standstill, these main burners are always used to restart the furnace”. That is also prescribed in the standard – it is a mandatory step to comply with DIN EN 746, the engineer adds.

Fault Diagnostics Were the Challenge

In the past, the start-up burners were controlled via a module, while flame monitoring occurred via UV cells at ignition. If one UV cell was defective, the whole plant would stop and would need to be restarted. Each restart would take at least 40 minutes because unburned gases containing nitrogen had to be expelled first. The defective UV cell also had to be replaced each time. That was a real game of hide and seek because you never knew which UV lamp had failed. As a result, the downtimes were considerable. Troubleshooting was also inefficient: although the burner control module forwarded information about the gas and air supply and UV detectors to the PLC, the opportunities for analysis were limited and time-consuming. “And we couldn’t make any changes on the controller because it only acted as a black box, so it was only responsible for recording the data from the PLC signals”, De Sloover explains.

A new Automation System

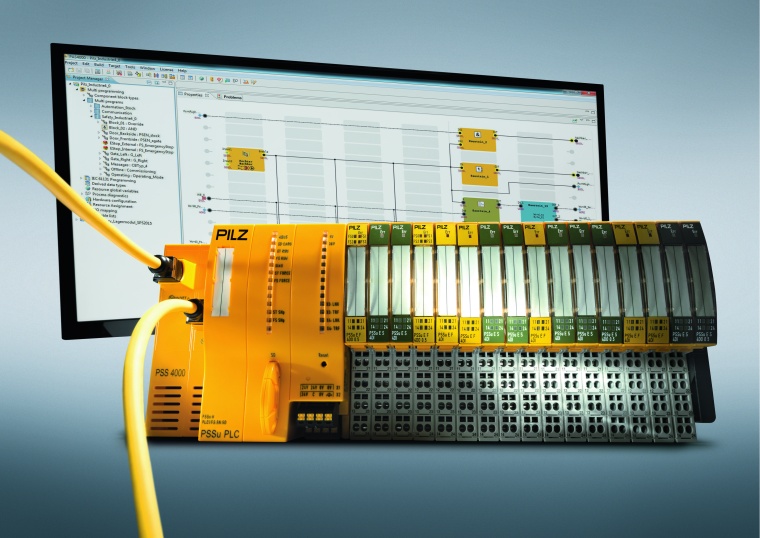

Downtimes had to be drastically reduced. “First we switched to ionisation instead of UV detectors. The second step was to replace the ‘old’ burner control module,” said Ives De Sloover. The ‘replacement’ was the Pilz automation system for automation and safety, the PSS 4000. The Belgian steel manufacturer already had positive memories of the German automation solution supplier from an earlier collaboration: “We had already installed a Pilz safety solution on another plant and were completely satisfied with the quality of the components, the service and also the support. We were already familiar with the automation system and thanks to its scalability it represents a forward-looking solution”, says the engineer.

One-Stop Competence

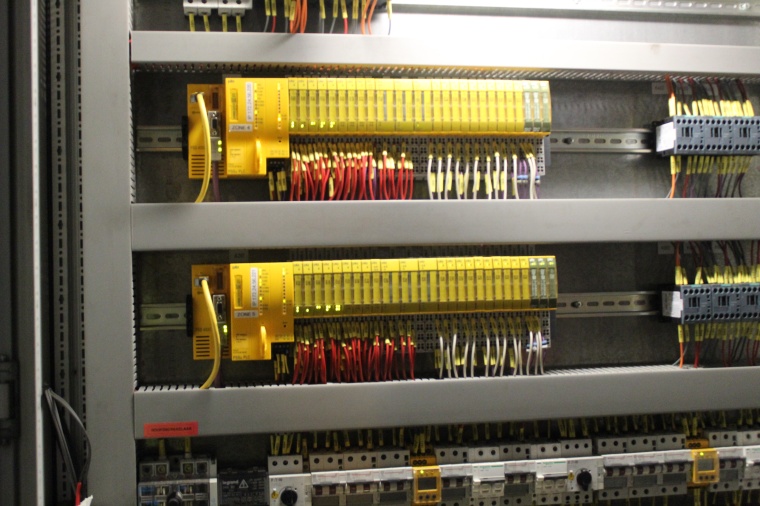

Pilz directed the whole procedure for converting the cold rolling mill. The blast furnace is divided into 5 zones, each with 10 burners. Zone 3 was the first to be converted. The first step was to document the specifications of the module that had been used previously. Pilz then transferred these design specifications to the automation system’s PSSuniversal PLC controller. The aim was a longer mission time and speedy, therefore adequate diagnostic options. So efficient visualisation to display the status of the burner was installed alongside the PSSuniversal PLC in a new, designated control cabinet.

As the burners run through various steps and sequences in accordance with the standard and must meet certain conditions in doing so, the visualisation was designed to guarantee the operators’ ability to read this status on the display at a glance. “Also, the flame is displayed graphically on all 10 burners and the sensor data from the burner controller is shown on the display, so it’s now possible to react much more quickly when a value is too low at any point”, says a delighted De Sloover.

Finally, in zones 4 and 5, an additional control cabinet with two PSSuniversal PLC was installed for both zones. Their status can also be read on the display in zone 3.

Flexible Software Blocks

The PAS4000 software from the automation system PSS 4000 can be used to configure function blocks, which focus on specific application scenarios; in this case, the burner application. With the burner management software package it is possible to implement programs to control various burner types simply and flexibly and to perform safety functions such as safety gate contacts, E-STOPs and light curtains. The use of ready-made, certified function blocks for burner management not only simplifies installation but validation too.

Numerous other function blocks are available in the software for the automation system. Ives De Sloover describes the benefits of the system and its software package in a nutshell: “A huge advantage of the automation system is that it allows applications to be implemented to meet customers’ specific needs.

Business Partner

Pilz GmbH & Co. KGFelix-Wankel Str. 2

73760 Ostfildern

Germany

most read

GIT SECURITY AWARD 2026 - The winners have been announced!

GIT SECURITY AWARD 2026: The best safety and security solutions of the year - now an overview of all winners

Safety and Security in an Emergency: How companies take responsibility with strategic personal protection and amok prevention

Personal protection & amok prevention: strategic concepts, training & responsibility for corporate safety and security

When the Internet stumbles: Why DNS is important

When DNS fails, the internet stumbles-AWS outage proves resilience and redundancy are vital for digital trust

Is Your Venue Ready for Martyn’s Law?

Martyn’s Law demands stronger security by 2027. Is your venue prepared to protect and respond?

Integrated and Futureproof: Traka’s Next Chapter

Interview with Stefni Oliver on Traka’s Vision for the Future