Machine & Plant Safety: The Winners of Category A at the GIT SECURITY AWARD 2025

The industry is alive - and more innovative than ever. Once again, users, readers, market participants and fans of certain products and solutions have made their choice, the winners have recently been announced and can now be admired and celebrated. Read here who wins a GIT SECURITY AWARD 2025 in the field of machine and plant safety and why.

This is the twentieth time since 2005 that GIT SECURITY International has presented this pioneering award for innovative, economical or influential products, solutions or services in the industry.

Further information on the GIT SECURITY AWARD - and all other winners here.

1st Winner Category A: ABB STOTZ-KONTAKT with JSD-TD25P-320700

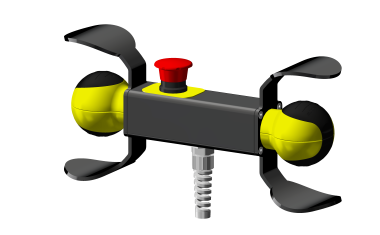

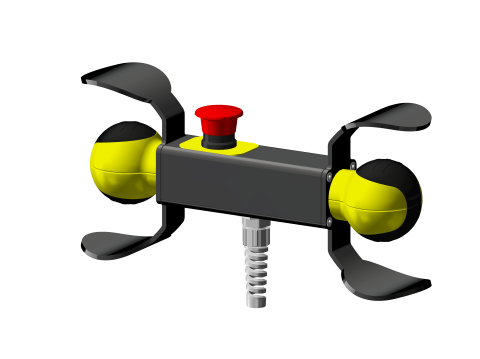

The mobile two-hand control unit from ABB offers maximum safety and exceptional flexibility. Depending on the risk assessment and equipment of the product, it can be used as a two-hand control or as a mobile operating unit in accordance with the applicable standards.

Optionally, the mobile two-hand control unit can be equipped with an Eden sensor, which ensures safe position monitoring. The robust aluminum housing ensures longevity, while the compact design enables easy handling. Thanks to the ergonomic design with Safeballs mounted on the sides, operation is extremely comfortable. Optionally integratable functions such as an emergency stop button and cables expand the range of applications.

Compared to classic, stationary two-hand control units, the ABB mobile control unit stands out thanks to its ergonomic design with Safeballs mounted on the sides. The two-hand control unit can be used in a mobile manner, for example for maintenance purposes, ensuring a high level of safety. Additionally, it is characterized by its lightweight and compact design.

Contact and further information in the ABB Company Channel

2nd Winner Category A: Euchner with Electronic-Key-System EKS2

The latest generation of its key systems, it is simple to implement, simple to operate and simple to adjust. The components: Read unit, evaluation unit, EKS2 Electronic-Key and Programming station, digital access control and selection of a safe operating mode

Security transponder with proven AES encryption, Profinet communication, simple integration into the bus system via Profinet switch, connection of 1-of-n safety outputs to a safe control system, highest safety level PL e, Project configuration through only individual parameters via the GSDML file, compact dimensions, industrial keys and a hygienically designed read unit.

- Simple implementation thanks to project templates with predefined functions and data fields.

- Simple assignment of access rights via input screens.

- Simple authorization blocking via an expiration date.

- Simple implementation of security standards for data handling and the assignment of rights.

- Simple integration in any PROFINET environment and systems from any manufacturer.

Contact and further information in the Euchner Company Channel

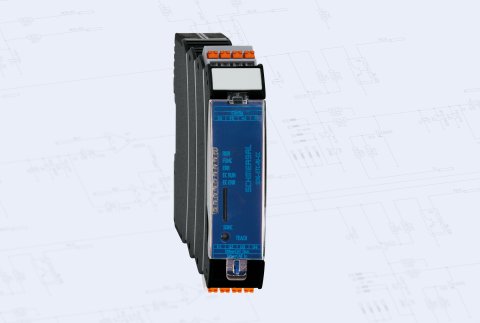

3rd Winner Category A: SCHMERSAL with SDG

Electronic safety sensors and solenoid interlocks with SD interface can transmit comprehensive diagnostic data to a higher-level machine control system. The data from the series-connected safety switching devices (up to 31 devices) is sent to the SDG fieldbus gateway via the SD bus and from there to the machine control system via the fieldbus.

For example, error messages - such as overtemperature, defective actuator or invalid combination of actuators - can be forwarded. Advantages: improved fault diagnosis, minimisation of downtimes, increased productivity, lean wiring, extensive additional functions via integrated web server and long-term storage of log messages via microSD card.

The new SDG fieldbus gateway has a web server and a microSD memory card and therefore offers the following features:

- Event logs can be evaluated in real time via the web interface.

- Complete diagnostic data from all safety switchgear devices are displayed in plain text in the browser window

- Devices, such as interlocks and control panels, can be controlled directly via the web interface

- The microSD card allows event logs to be exported for evaluation and long-term storage.

- The configuration of the series connection is stored on the microSD card to enable seamless device replacement in case of error.

In the near future, Schmersal will further expand the functionalities of the SDG fieldbus gateway so that the data of the connected safety switchgear can be transmitted not only via EtherCAT, but also via the common fieldbus protocols PROFINET, EtherNet/IP and Modbus. In addition, networking options will be expanded through connection to IO-Link and OPC UA communication systems.

Another benefit of the SD bus system: by connecting sensors and interlocks with the SD bus in series (an SD Gateway can communicate with up to 31 safety switchgear devices), this safety solution enables extremely lean wiring and reduces costs without sacrificing Performance Level (series connection for applications up to PL e). Setup and commissioning of an SD installation have been designed to be as convenient and straightforward as possible and all devices receive addresses from the Gateway automatically.

Contact and further information in the Schmersal Company Channel